Digital Design & Fabrication Specialist

Computational Architect

Visual Artist

Mehran Masoudi

My Journey

My Portfolio

My E-mail

My LinkedIn

My Instagram

My CV

Visualization & Animation

Rendering & Post Production

Architectural Environment 3D modeling

Architectural Animation & Walk-through

Product 3D Modeling & Presentation

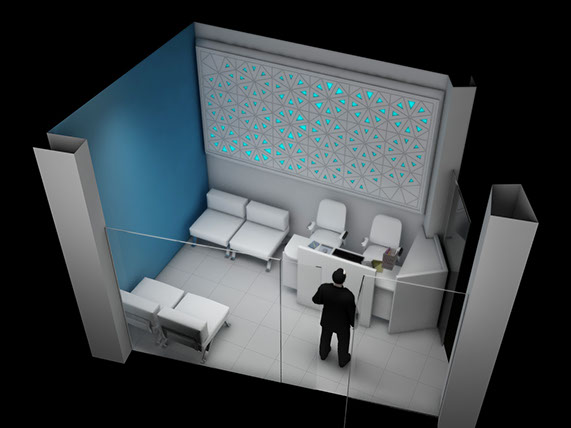

Interior Space Visualization

3D Studio Max | Expert

Lumion | Advanced

Adobe Muse | Advanced

Adobe Photoshop | Intermediate

Adobe Premiere | Intermediate

Architectural Computation

Algorithmic Optimization

Parametric Architecture Design

Architectural Drawing Automation

Detail Design & Manufacturing

Geometrical Problem Solving

Rhinoceros 3D | Advanced

Grasshopper | Advanced

Python Script | Intermediate

Auto CAD | Advanced

Autodesk Revit | Intermediate

Digital Fabrication

Arduino Programming & Responsive Tools

CNC Milling Machine G-Code & Operation

KUKA Robotic Arm Programming & Operation

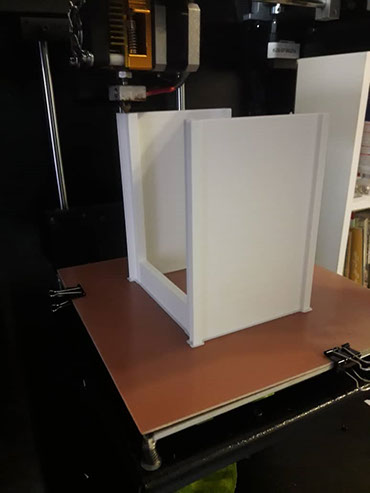

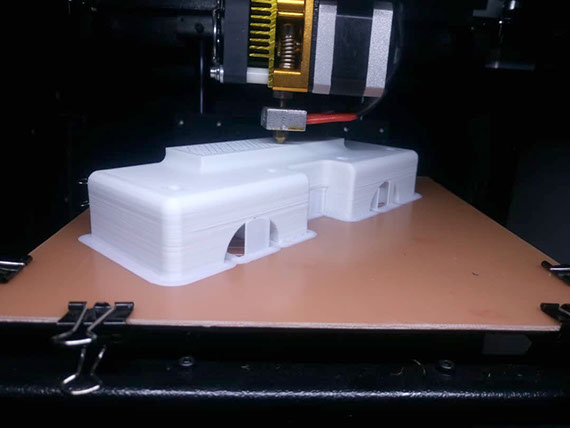

Printing with FDM & Resin 3D Printers

Digital Prototyping

Laser Cutter | Advanced

CNC Milling Machine | Advanced

3D Printier | Intermediate

KUKA Robotic Arm | Advanced

Arduino & Electronics | Intermediate

Education, Job Experience and Expertise

Chapter 4

My time in Dahi Studio

My friends and I have been working together for a long time. After reaching a sufficient level of knowledge and mutual understanding, we officially established our cooperative pact in November 2016 under the name of Dahi Studio. Since our establishment, Dahi Group has been providing various services in the field of architectural engineering, including architectural design and visualization, architectural computation, digital design and fabrication. We also hold workshops related to these topics for architecture enthusiasts and students. Our service has been ongoing since then.

Design & Visualization

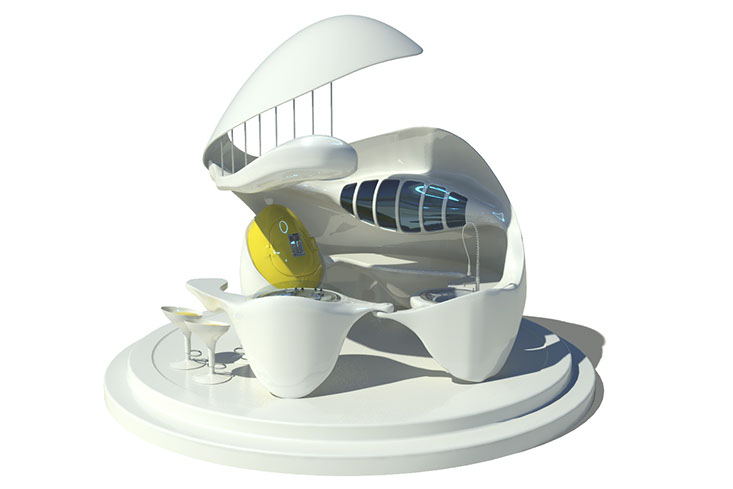

At the outset, the studio mainly worked on traditional architectural design and visualization projects.

<

>

<

>

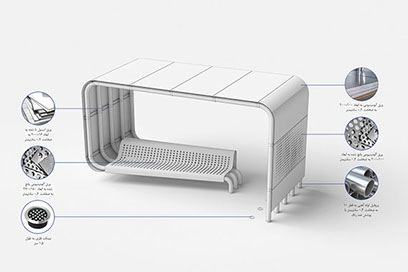

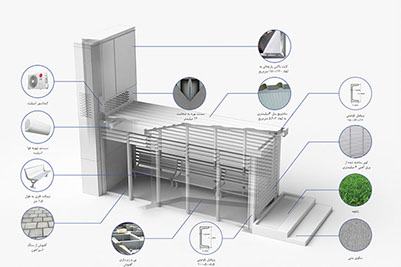

2019-6 & 7 | Kish Stop

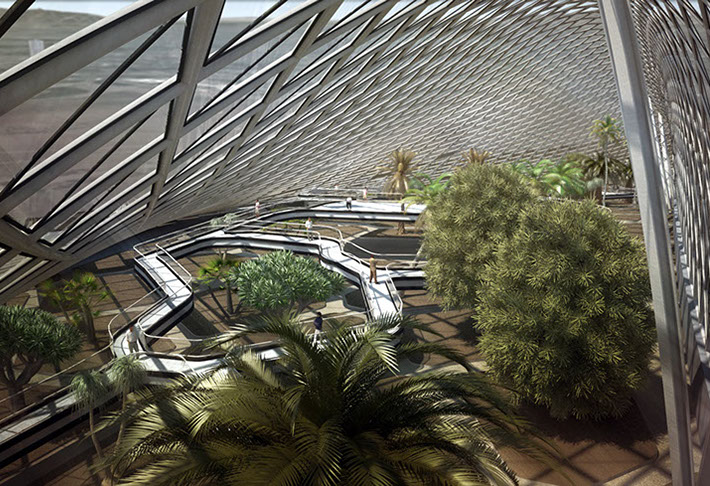

In order to improve the transportation infrastructure in Kish Island, we were assigned the project of designing regular and enclosed stations.

we proposed more than ten alternatives for the stations to the client. Three of these designs were selected for construction. I used Lumion extensively to present our ideas.

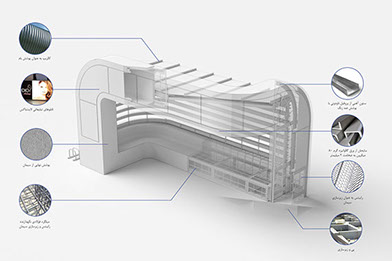

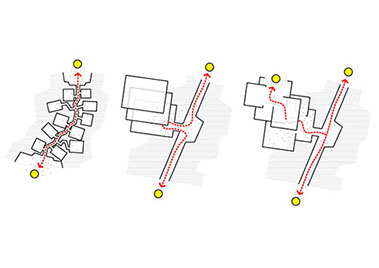

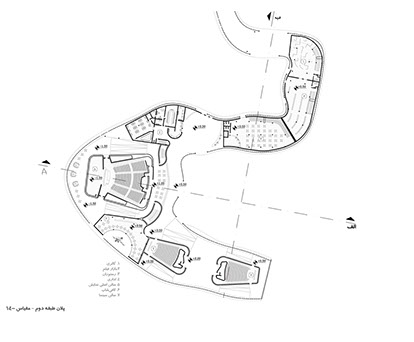

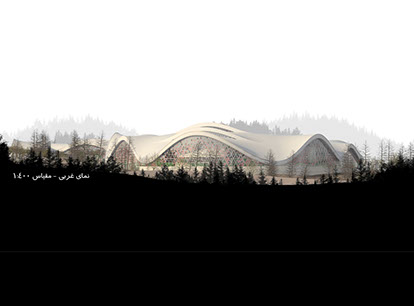

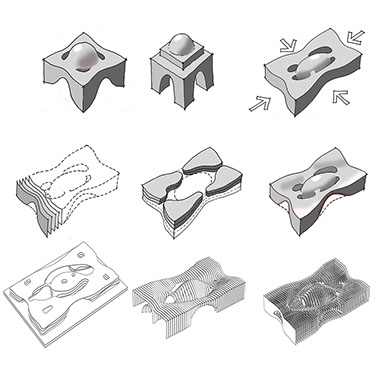

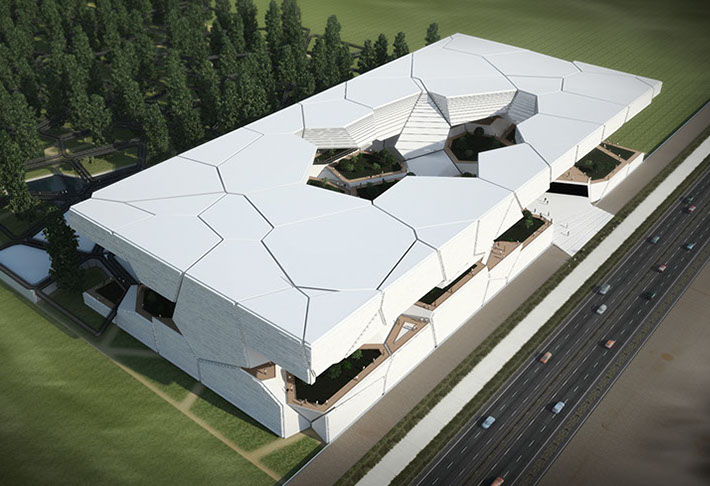

2019-12 to 2020-2 | Motel Ghoo

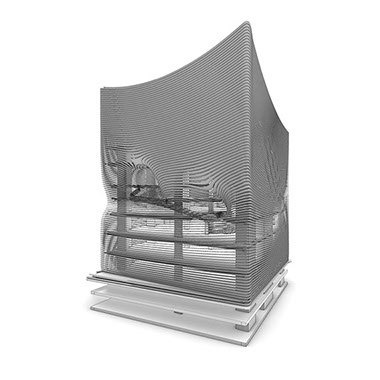

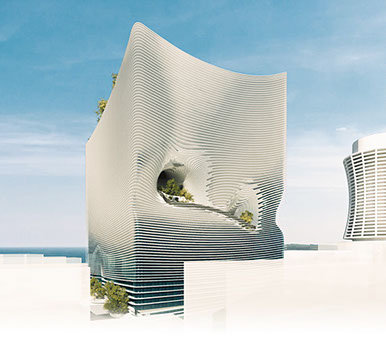

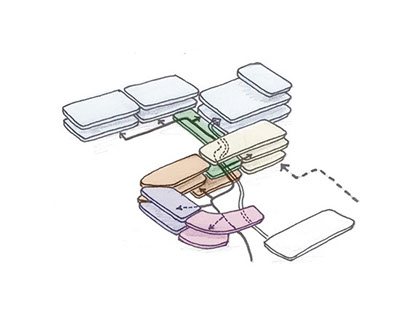

We presented two design options for the commercial center at Motel Ghoo beach (now known as Salman Shahr)as part of a competition. Our proposals were based on an analysis of users' behavior and their circulation in the architectural space, and the functions of surrounding structures, as well as the potential view of the beach and ocean. My knowledge of advanced modeling and algorithmic design was essential in achieving our goals in this project.

2018-5 & 6 | Kish Artificial Island

In this animation project, I had to depict the purpose of the project, which was to build an artificial island in the northeast of Kish Island, by showing the excavation and embankment process, vehicle and pedestrian access points, the master plan of the project and distribution of different functions and buildings.

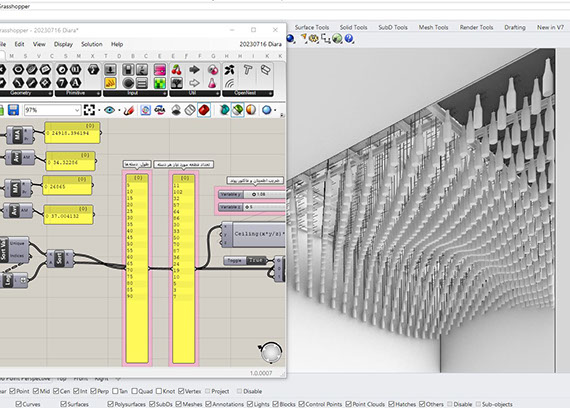

Architectural Computation

Over time, our group was able to attract projects that aligned with our expertise. These projects could only be accomplished using computer processing power and algorithms. Without these computational tools, tackling upcoming issues would be impossible, time-consuming, and expensive. Some of the most important tasks in these projects include solving geometric problems, automating manual processes, and identifying and correcting possible errors.

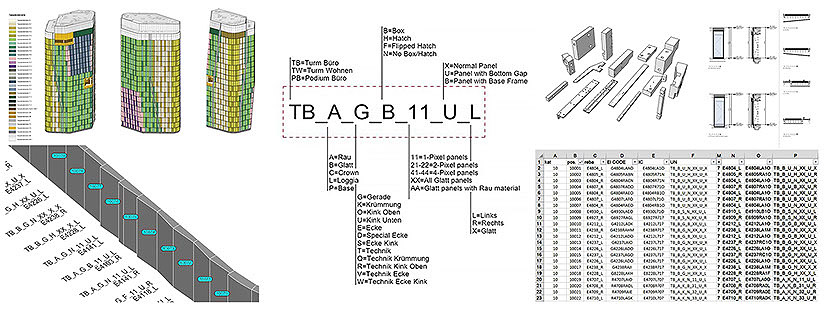

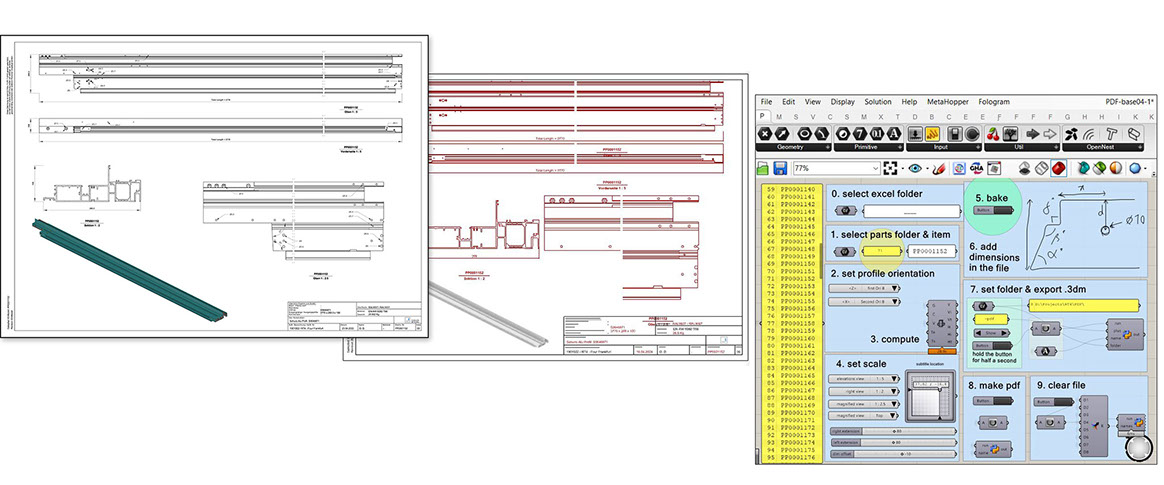

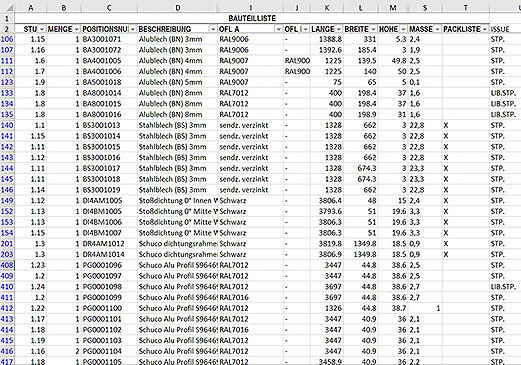

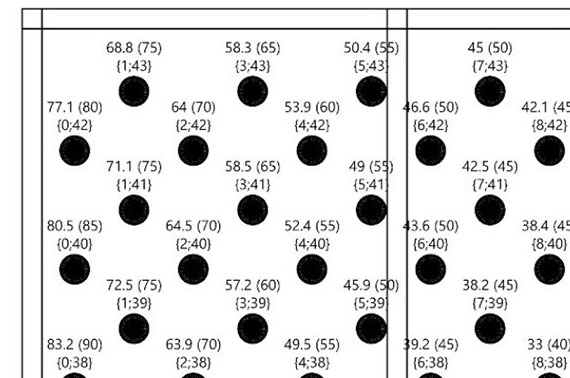

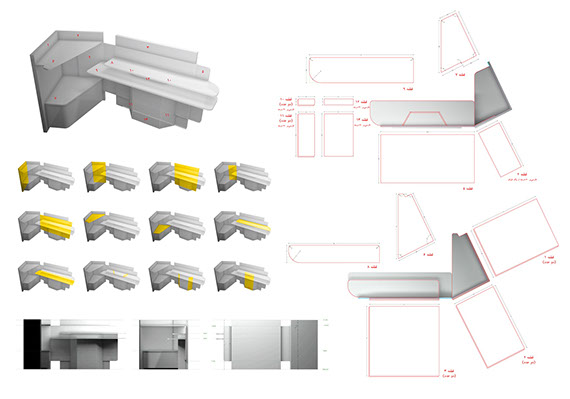

1. Analyzing Data:

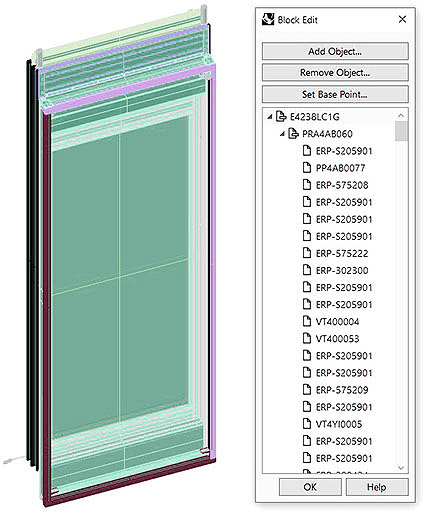

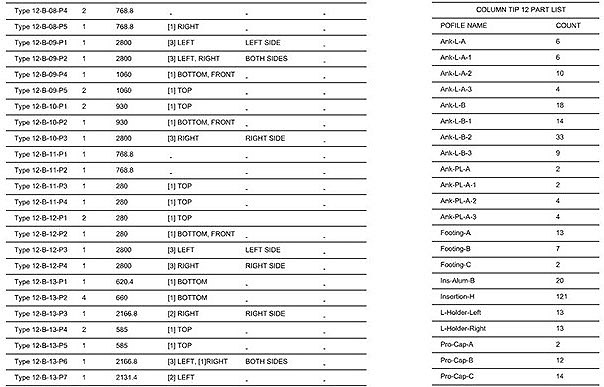

The first step in our process was to collect all the data provided by the client. They had already modeled some units and their assembly parts. We stored these parts in a library for future use, as many of the upcoming units would use the same or slightly altered parts.

2. 3D Modeling the Unit Assembly:

Next, we modeled the unit assembly in 3D using the unique name of the units, based on our naming system. We either used the parts already present in our library or created new ones. We then assigned a new name and ID to each newly created part and added it to the library. It was crucial to compare the new parts to all the preexisting ones in the library, and we developed an algorithm to compare them based on geometrical features.

3. Extracting Structure List:

After modeling the unit assembly, we needed to extract all the elements of the unit as separate files. Each unit had numerous parts, so we used Python to write a script that exported all the parts at once. Additionally, we created another script that generated an Excel file containing all the information necessary for the fabrication of the unit, such as the part names, dimensions, and quantities.

2022-4 to 2022-7 | Four Frankfurt RT4

FOUR is the vision of a new city. Four unique high-rise buildings shape and change the face of the metropolis of Frankfurt - with forward-looking architecture and a sustainable urban development concept.

In collaboration with Emre İstikam, our team was responsible for creating construction documents for the facade of the fourth tower, also known as RT4. These documents were necessary for the production, fabrication, and assembly of the facade unitized panels. To simplify the process, we utilized our computational skills to automate various BIM-related tasks, including generating the model, detecting clashes, validating geometry, creating shop drawings, creating a vendor list, and generating a material take-off. We achieved this through scripting and visual programming using Grasshopper, which saved a significant amount of manual labor and man-hours.

My role in this project was to analyze the primary data, carrying out the feasibility studies, developing algorithms and scripts for exporting STL files, substructure list Excel files, and automating and supervising the shop drawing process.

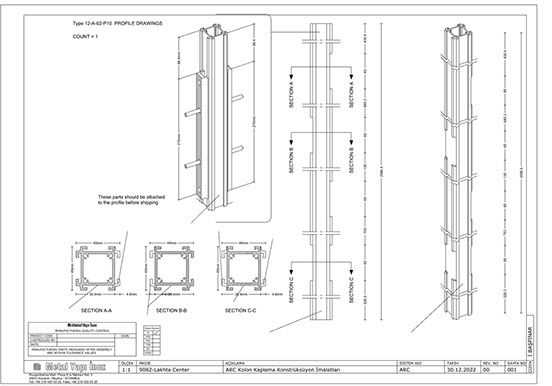

4. Preparing Shop Drawings:

The next step was to provide the manufacturing process with shop drawings of the parts. We automated most of this process using an algorithm. The user would refer to the 3D model of the part and specify the appropriate orientation. Running the algorithm would provide the user with a shop drawing of the part, including an isometric image and side views with dimensions.

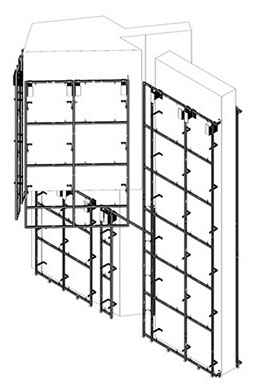

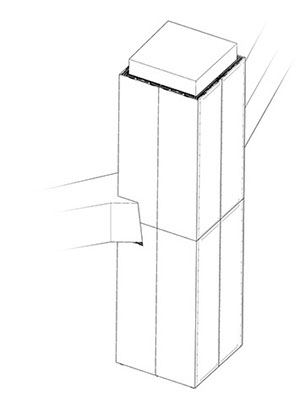

2023-3 to 2023-7 | Lakhta Center

Gazprom Tower is europe’s tallest skyscraper and the world’s northernmost high-rise. The multifunctional complex housing Gazprom’s headquarters and public areas is based in St. Petersburg on the coast of the Gulf of Finland.

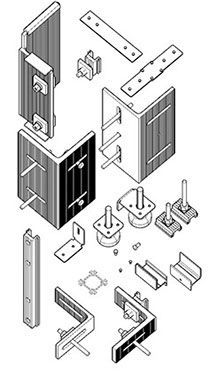

In our collaboration with Emre İstikam, we were entrusted with the task of providing the client with all the information and details required to cover the interior walls and columns of the lower levels of the tower with steel sheets. This included the 3D model of the substructure and the installed finishing sheets, along with a part list, dimensions, and positions of the parts on the walls and columns. Working on twisted columns proved to be more challenging.

We received the top and bottom sections of the columns as-built, which formed the basis of our input. We developed an algorithm that generated the best fit untwisted geometry for each column, taking into account obstacles like beams, and then generated the substructure entirely. Another algorithm generated the sheet panels along with their connected parts. Finally, we wrote an algorithm that automated the process of generating all the shop drawings with necessary details attached.

I was responsible for developing the algorithms for geometry optimization, substructure model generating, and shop drawing automation process.

Substructure Assembly

3D Model of a Wall Substructure

3D Model of a Twisted Column Substructure & Finishing

Main Parts & Elements

Generated Shop Drawing Sheet

Generated Part List

2020-4 | Aluminum Panels Unroll

The input data in this project was the geometric position of the quadrilaterals of the finished surface of the facade panels in the form of a 3D mesh. The client desired panel construction documents that included the cutting and folding lines of aluminum sheets for all panels.

With the algorithm I developed, I was able to unroll all 830 panels and prepare the necessary documents, including automatic dimensioning, sheet naming and numbering, and map guides, in less than four days. Most of the time was spent preparing the algorithm. If this process was to be done manually it would have needed a lot of man power and time and most importantly it could have been done only once. The parametric nature of this process allows for changes to be made quickly, such as altering the length and bending angle of flaps. Additionally, the client can reuse this algorithm for similar projects.

Architectural computing saves a lot of resources and time, and also makes the process more flexible and reusable.

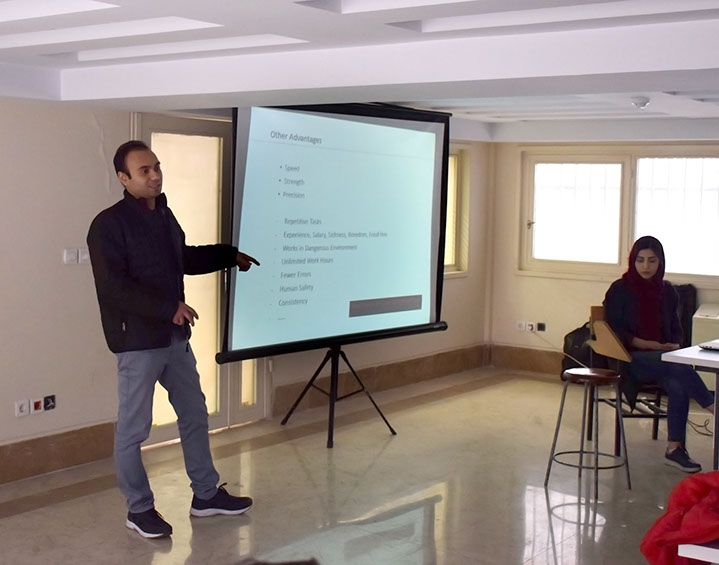

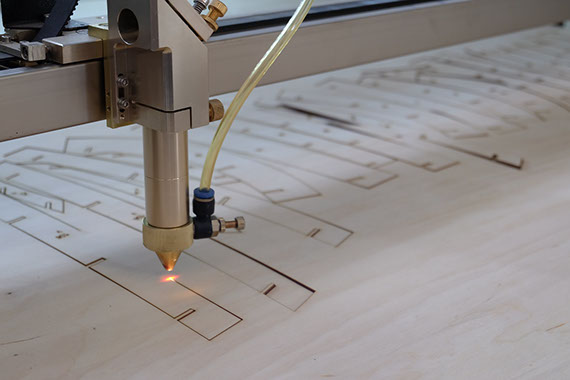

Digital Fabrication

The desire to apply the knowledge of computational design practically led us to hold educational workshops with the aim of design and fabrication using digital fabrication tools. After gaining initial experience in holding several workshops, we were invited by the Dean of the Faculty of Architecture at the Art University to equip the applied science laboratory of the university located in the Farabi campus of Karaj city. In this way, the digital craft house, also known as the FabLab of the University of Arts, started operating under the guidance of the Dahi group in the winter of 2019.

Here I learned and taught others the theoretical foundations of digital fabrication and acquired the ability to work professionally with commonly used digital fabrication devices such as FDM and Resin 3D Printers, a Laser Cutter, a CNC Milling Machine, a KUKA Robotic Arm, and Arduino. (2019-2 to 2023-6)

Workshops

I have experience in organizing and leading workshops, both prior to and during the establishment of Digital Craft House. The Dahi group utilized the laboratory's facilities to conduct workshops and classes centered around computational design and digital fabrication, aimed at improving the students' scientific knowledge.

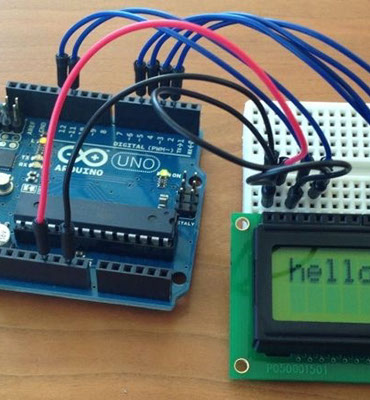

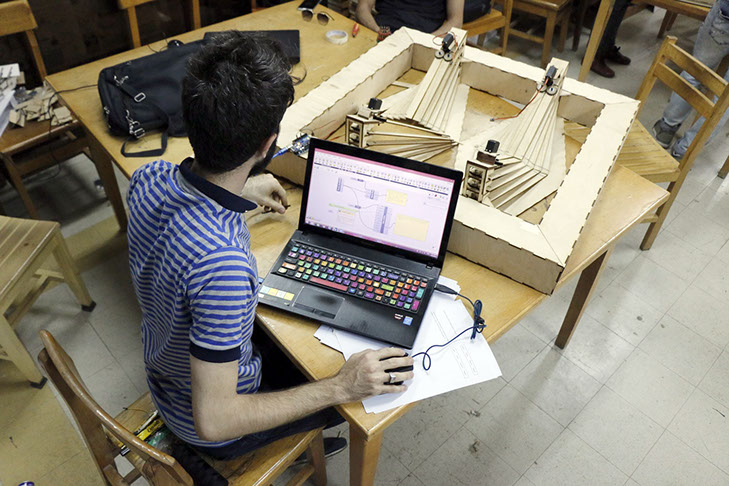

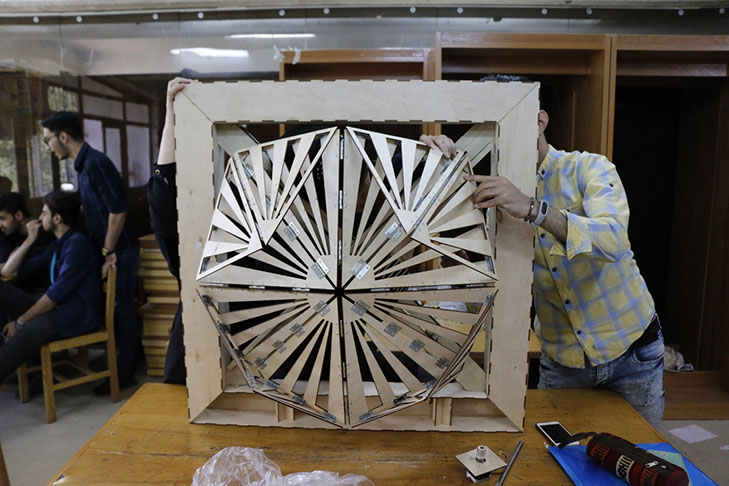

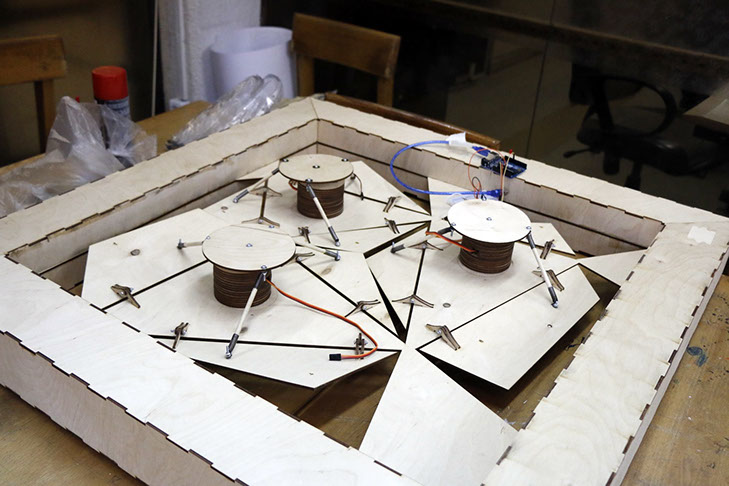

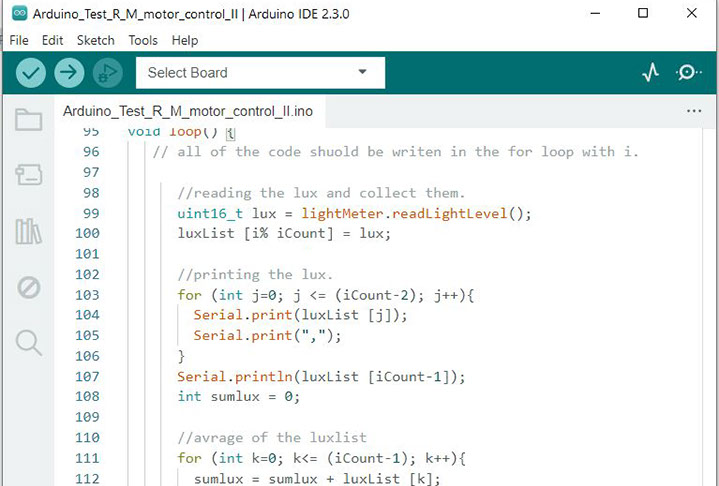

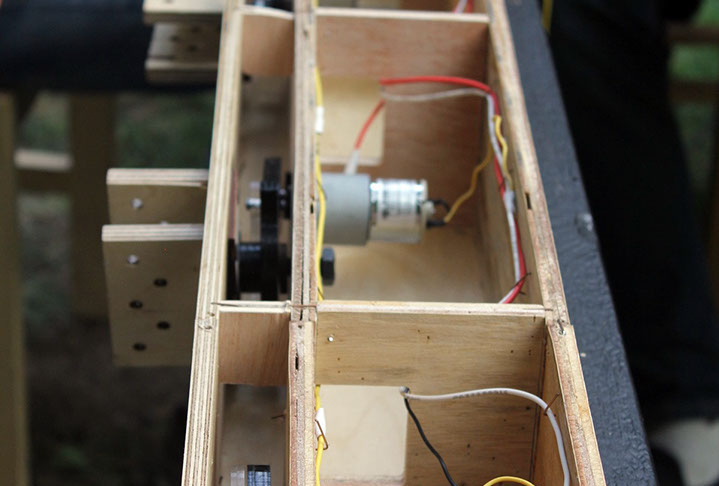

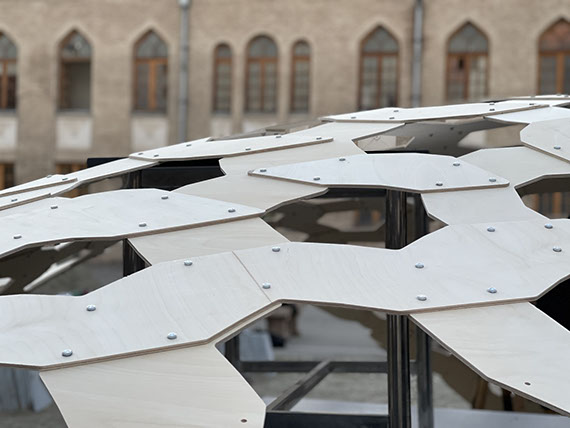

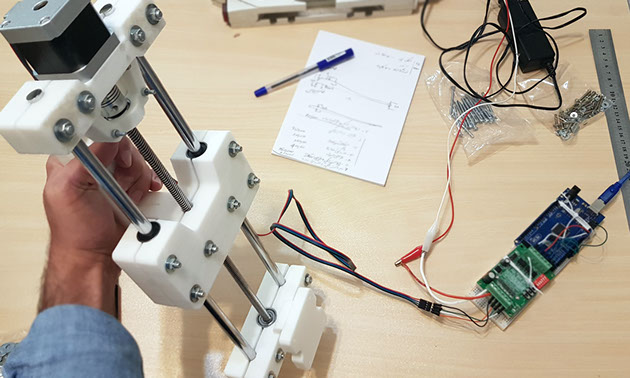

2018-5 & 6 | Adaptive Building Envelope

In the spring of 2018, Dahi Studio received an invitation from the Scientific Association of Architecture at Bualisina University of Hamedan to conduct a workshop on responsive facades. This workshop was a significant milestone for me as it marked my first experience as a lecturer in such an event. To prepare for the course, I quickly familiarized myself with the fundamental principles of electronics, programming the Arduino microprocessor, and the functioning of various motors like DC, Servo, and Stepper motors as well as basics of circuit design.

During the workshop, the participants designed plywood made window shades models that responded to changing lighting conditions to test their ideas. They used lumen meter modules and mostly Servo motors. We helped the program their Arduino microprocessors and making their circuits to achieve their desired results. In the end, with the help of the participants, we created a louver structure that served as a shade for one of the university's windows. All in all this workshop was a priceless experience for us as instructors and hopefully for the Buali University students as well.

Role: Instructor and responsible for designing and creating the circuit board and building the motorized parts of the final structure

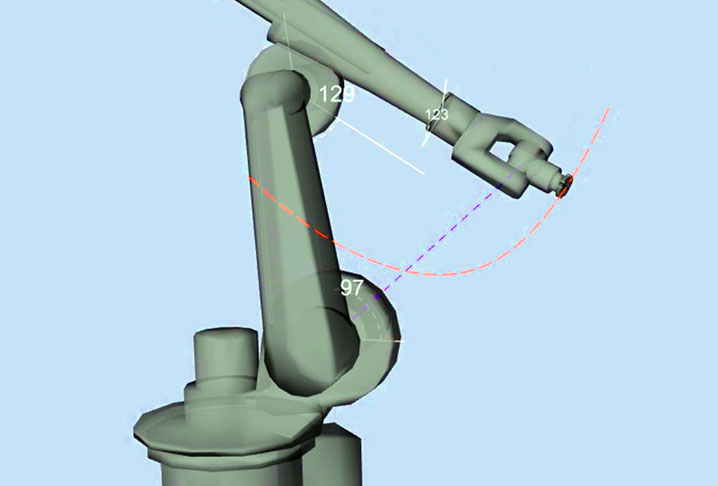

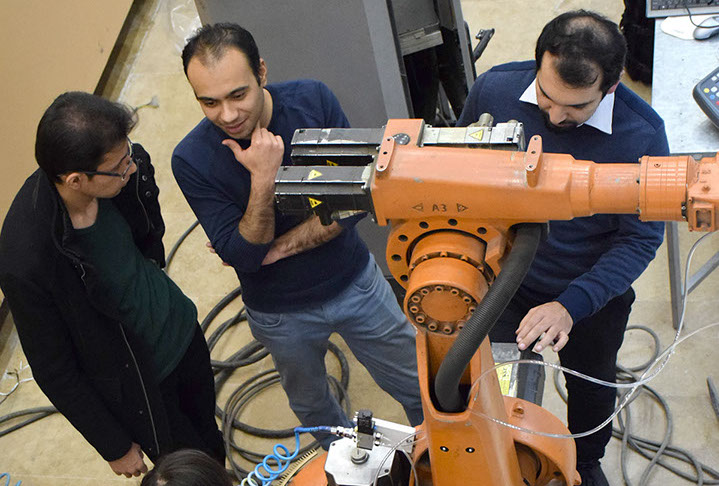

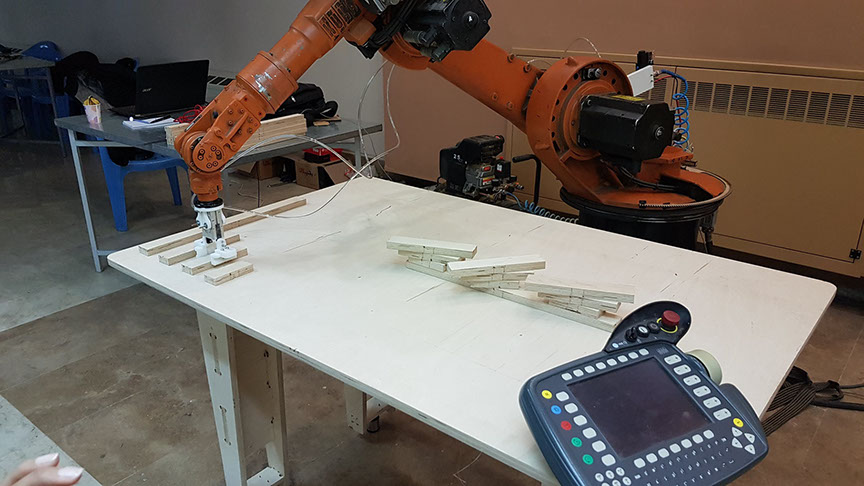

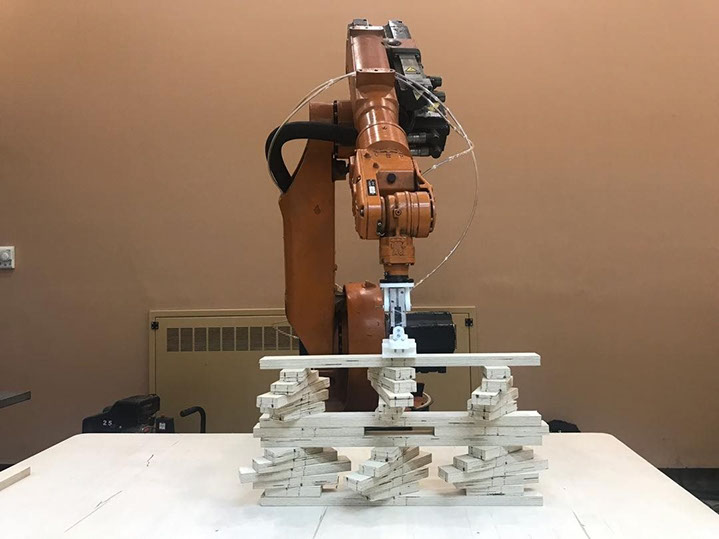

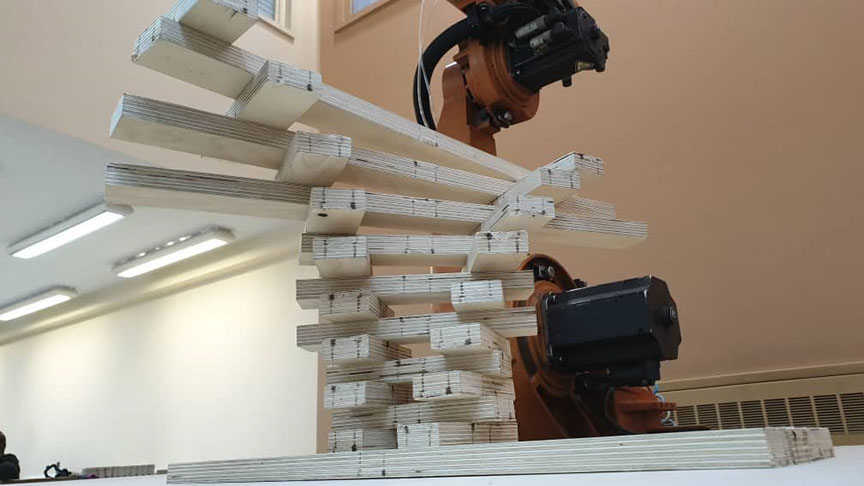

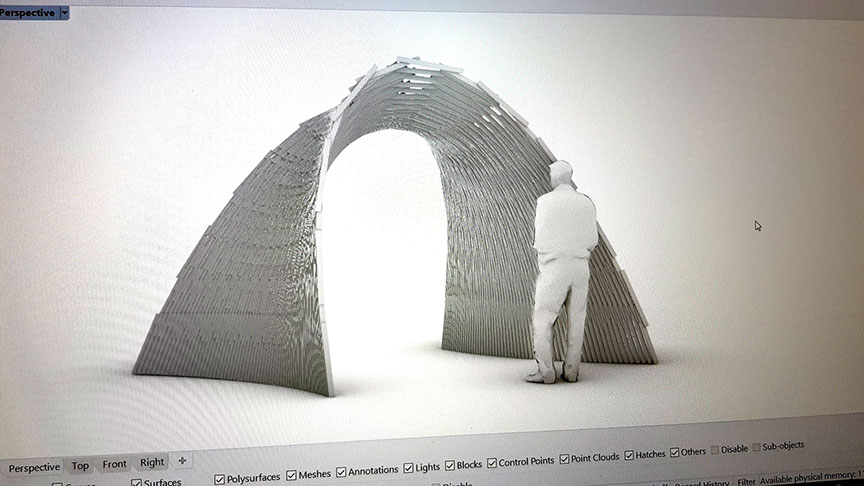

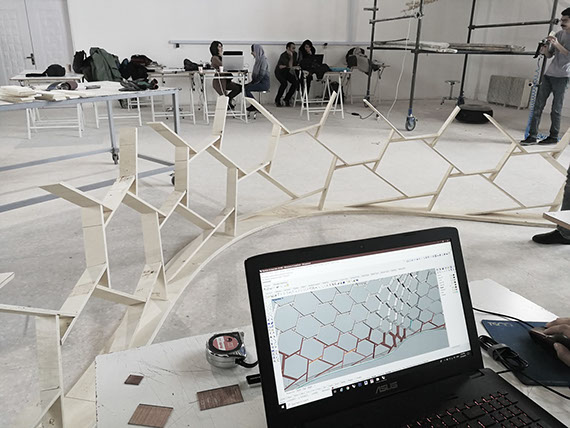

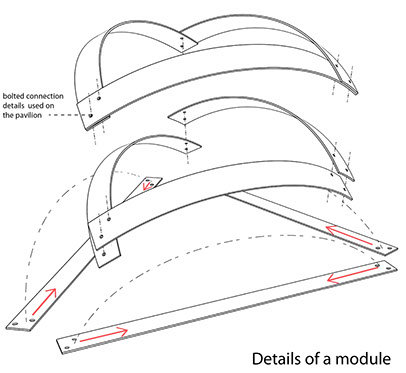

2019-11 & 12 | Robotism

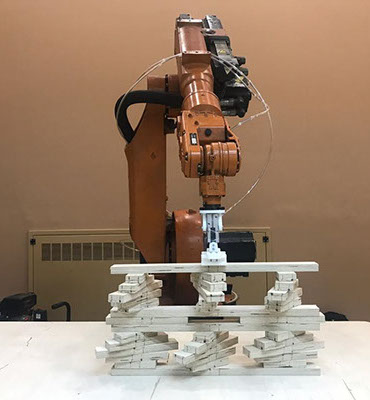

During the ten-day Robotism workshop held at the University of Tehran, participants focused on learning about computational design and robotic fabrication. The workshop utilized a KUKA KR6 robotic arm with a KRC2 controller. As the instructor, I had to master the principles of programming and operating the robot two weeks before the workshop, so I could effectively teach the participants.

The workshop started with an explanation of KRL Syntax and generating G-Codes, followed by several basic exercises to teach the concept of paths and target plane orientation in robot simulation. We also demonstrated the robot's capabilities with light painting using a simple LED placed on the robot's head, which yielded fascinating results. In the next exercise, students were asked to design simple arrangements of wooden pieces with specific sizes and numbers, and assemble them using the pick-and-place technique. The goal was to ensure that the pieces remained stable throughout the assembly process without the need for screws or glue.

Once the teams had completed introductory tasks and were familiar with practical challenges such as properly defining planes to prevent collisions with the robot arm, as well as installation of pneumatic gripper and air pump, they began designing a pavilion on a one-to-one scale. All the proposals were assessed, and one was ultimately chosen for the final project. Modifications were also made to finalize the design.

Role: Workshop coordinator, instructor and responsible for writing the KRL codes and robot operation

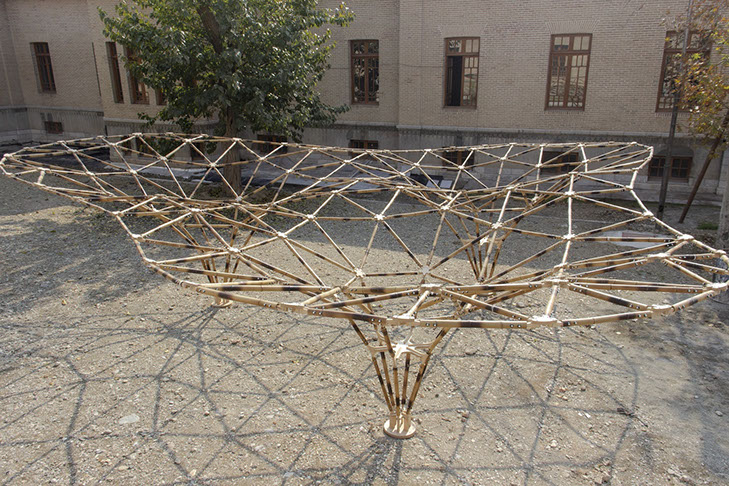

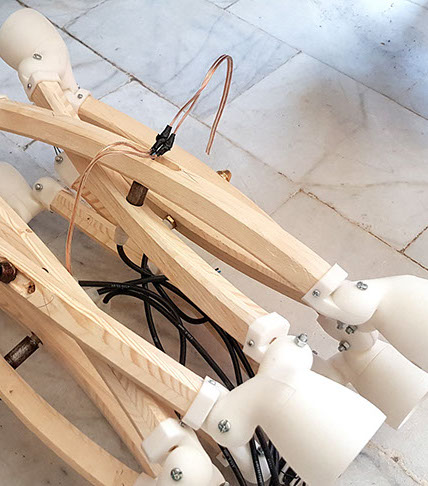

2021-5 to 2021-11 | Bamboo Bam

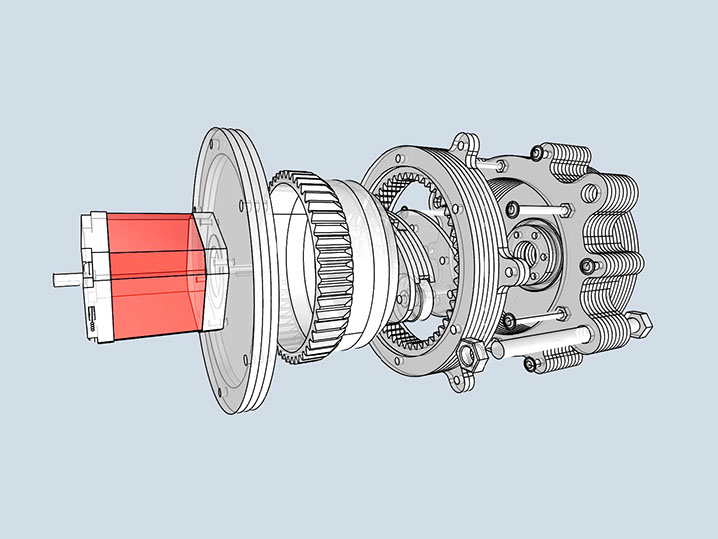

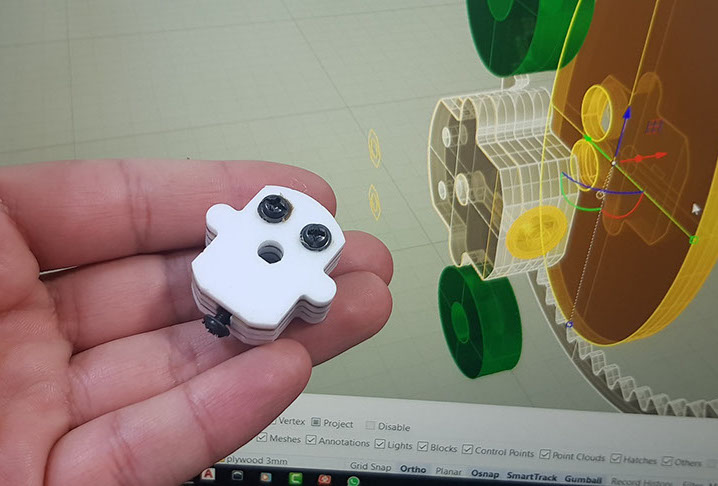

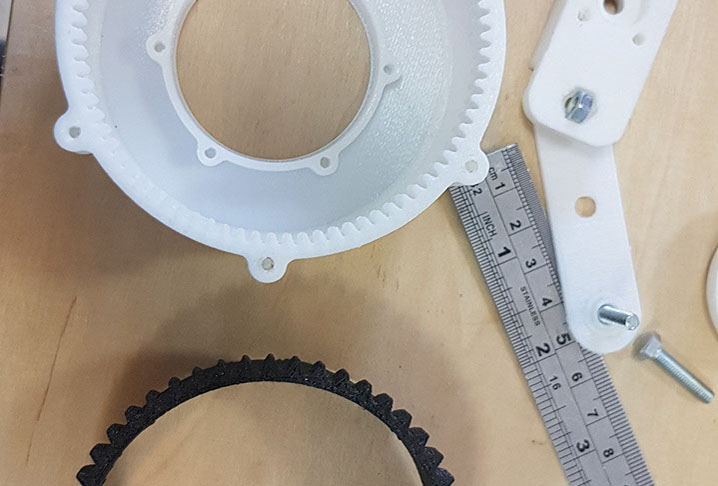

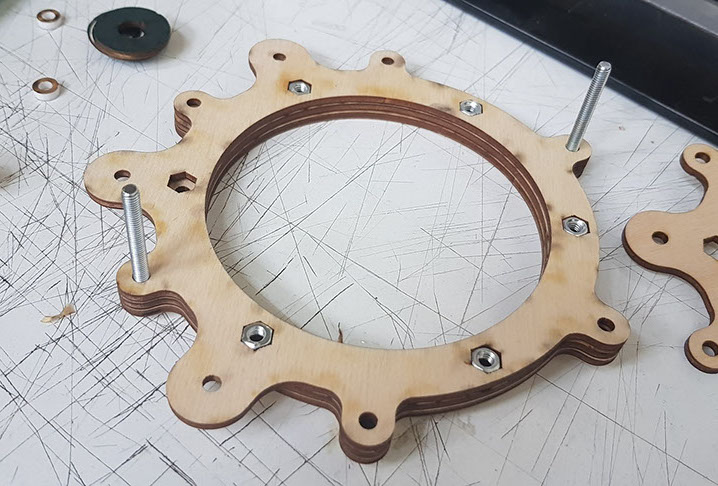

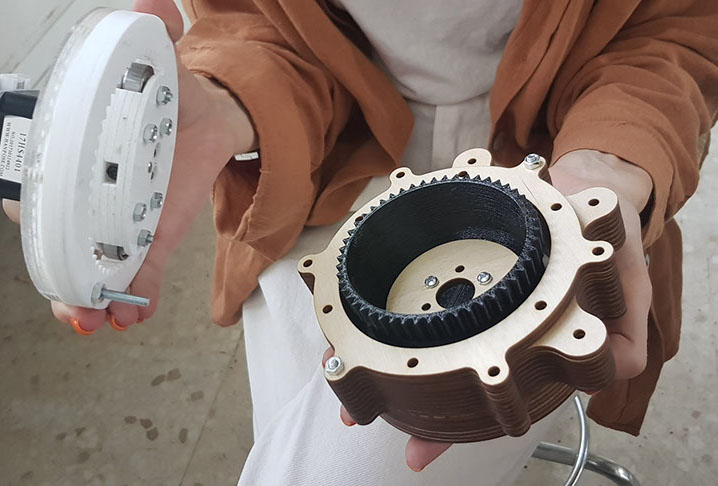

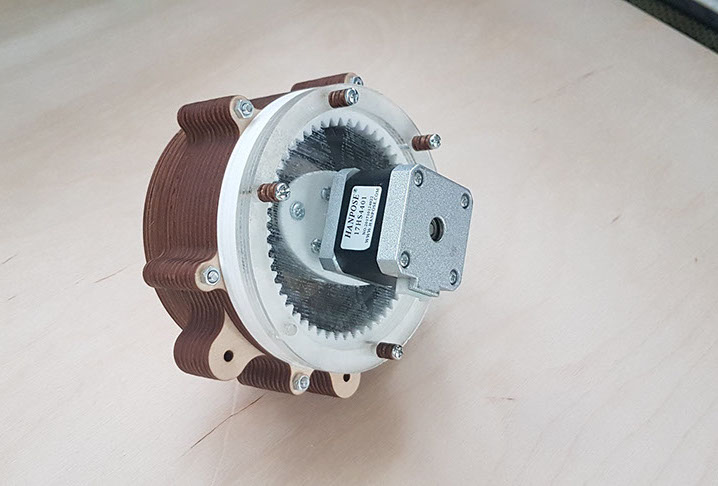

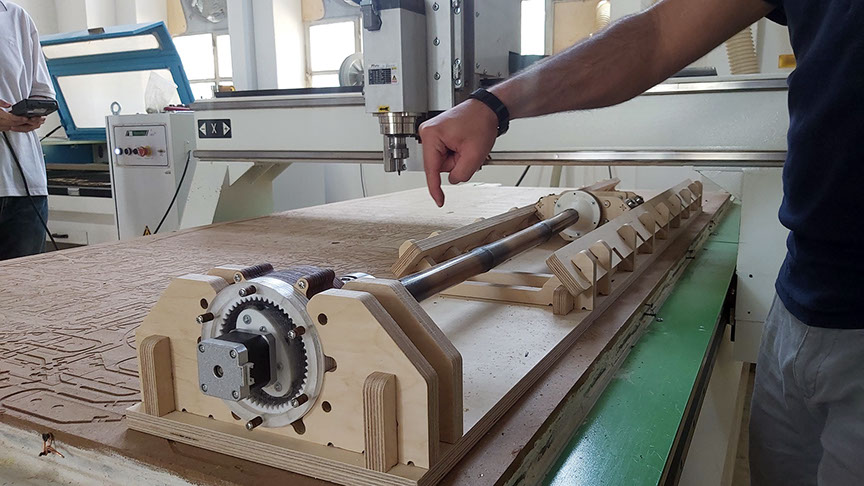

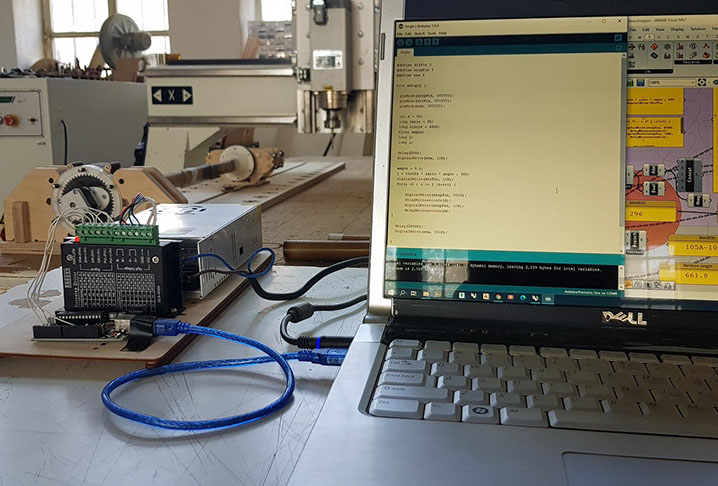

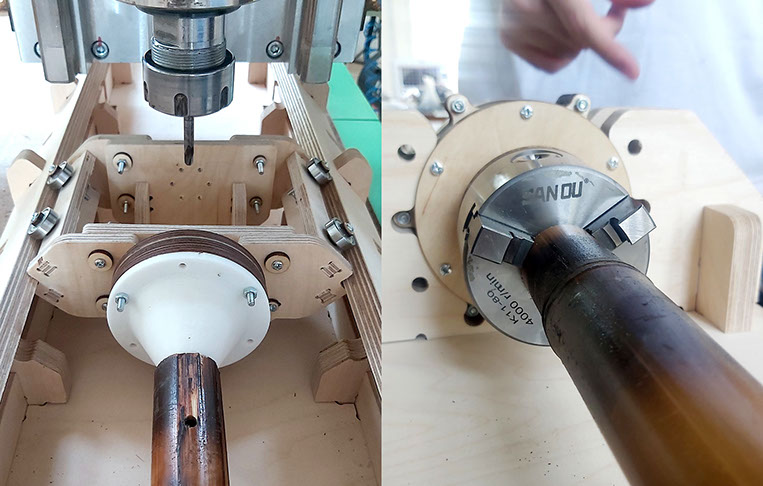

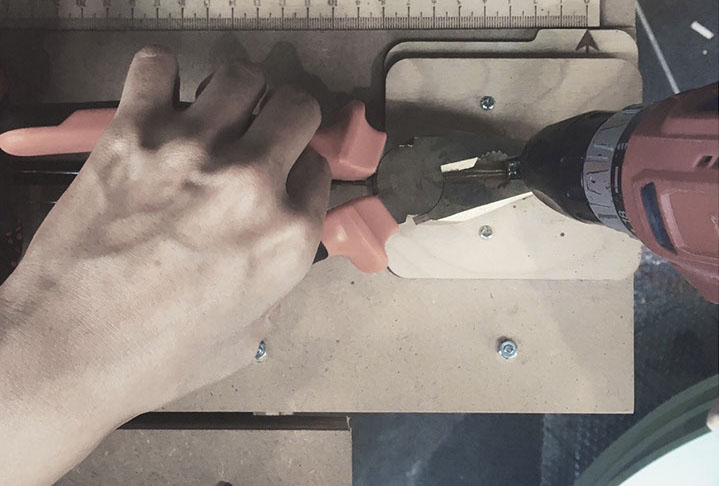

The workshop aimed to cover five key research areas, including material study, sustainability, computational design, form-finding, structural design, and digital fabrication. Instructors and collaborators from different institutions and backgrounds including me were gathered together to share our skills and experiences. Several systems were proposed, and after evaluating them based on visual elegance, ease of fabrication and assembly, structural performance, durability, and cost, a handful of them were shortlisted as final candidates. The elected system was prototyped and refined, and students were encouraged to participate in form design using either form-finding methods or freehand designs. The final form was then selected based on votes. To visualize the design in LOD 400, the team used BIM modeling to perform clash detection prior to fabrication and extract fabrication data. The result was a fully detailed 3D model that included labels for each element, which could also be used as a coordination model in the assembly process. Additionally, the team created shop drawings of the nodes and handles. These parts were to be milled from plywood sheets with a 3-axis CNC machine. For the drilling stage of the bamboo poles, I designed and fabricated a custom rotary tool mostly out of plywood. I also built a harmonic drive for the rotator using 3D printed and laser-cut parts, ball bearings, a stepper motor, and an Arduino board. The team then used the rotary axis and the correct tool path to start drilling the poles with the CNC milling machine. The rotation angles of each pole were retrieved from the BIM model previously prepared in Grasshopper. I wrote an algorithm to generate the Arduino program for each rotation using this information.

Role: Instructor and responsible for design and construction of custom rotary tool and Arduino programming

Lecturer at IASS (International Conference on Spatial Structures) 2021: "Post-Covid Hands-On Workshop"

<

>

<

>

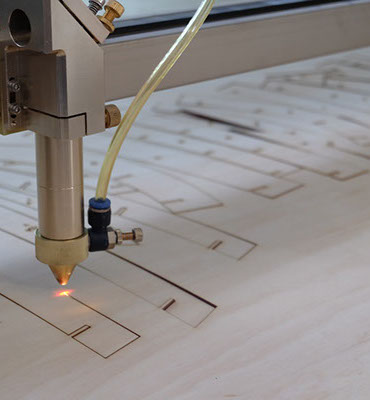

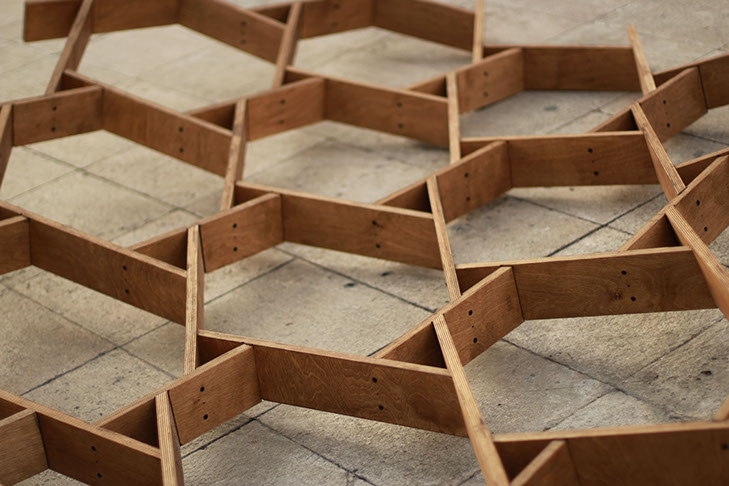

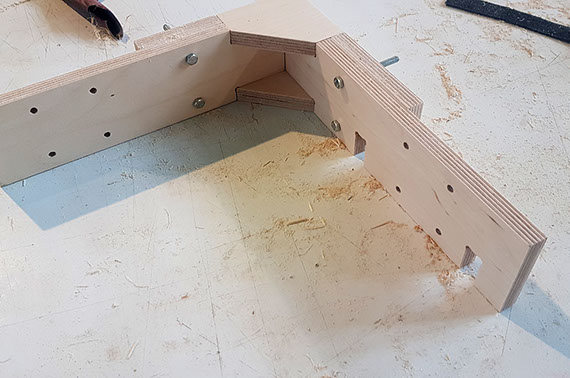

2019-3 & 4 | Nexorade

During this workshop, students studied the nexorade structure, aiming to design and construct a similar structure. Initially, they tried to comprehend the logic behind the nexorade. Then, they developed their designs using digital fabrication tools and produced them in real size. For the final structure, all parts of this structure were made of 12mm thick plywood, which was cut using CNC milling machine, and then assemble using nail gun. I was one of the instructors in this workshop. We introduced the basics of digital fabrication and the software and hardware tools, such as Rhinoceros 3D, Grasshopper, CNC milling, and Laser Cutter.

Role: Instructor and responsible for design refinement and fabrication of the structure

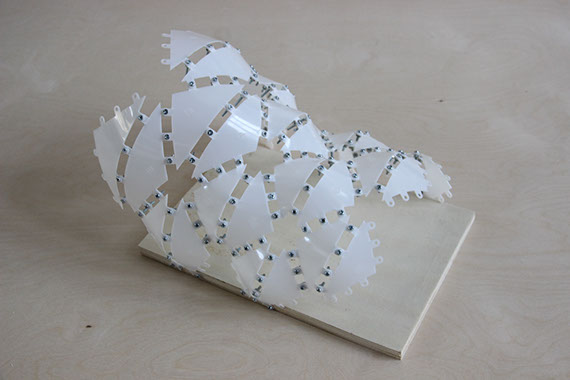

2019-8 & 9 | Surface Active Structures

In this workshop, we aimed to create two different structures by examining surface active and bending active structures. To start, we studied the materials and their behavior to develop ways to shape them.

We used digital fabrication tools to design and produce the structures at a real scale. All parts of the structures were made of plywood with thicknesses of 3 and 6 mm. Both final structures were bent to their shapes by applying force and utilizing the elastic properties of the materials.

Role: Instructor and responsible for fabrication of the structure

<

>

<

>

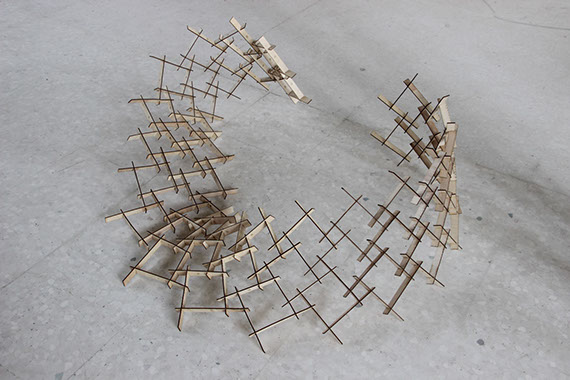

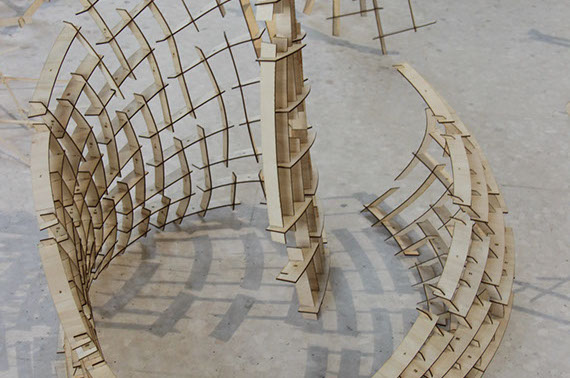

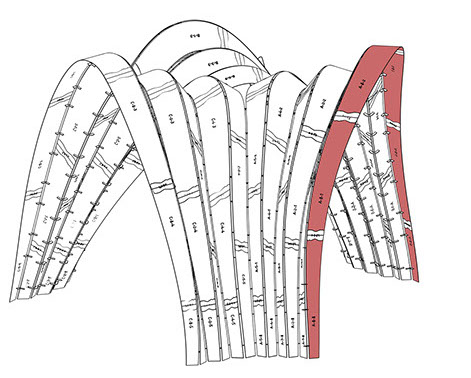

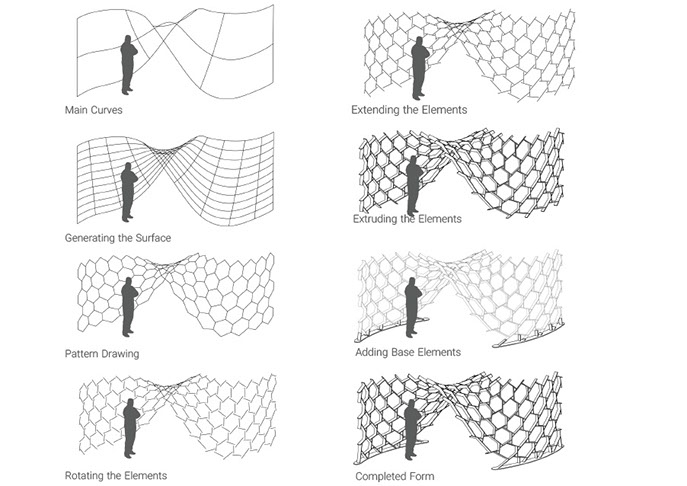

2021-11 & 12 | Bending Active Structures

The workshop's main output is a pavilion, situated in the courtyard of the Bagh-Melli campus. The pavilion is constructed using strip-like elements that are connected in two perpendicular directions, creating a three-dimensional bent in space that is stabilized in the same way. The final shape is achieved by assembling these pieces together.

To begin with, this form was digitally modeled using Grasshopper software. The unroll of each piece was then plotted. Additionally, some members were produced as stitching plates for these smaller parts to create a U-shaped form and bind the U-shapes together.

Role: Instructor and supervisor of fabrication process

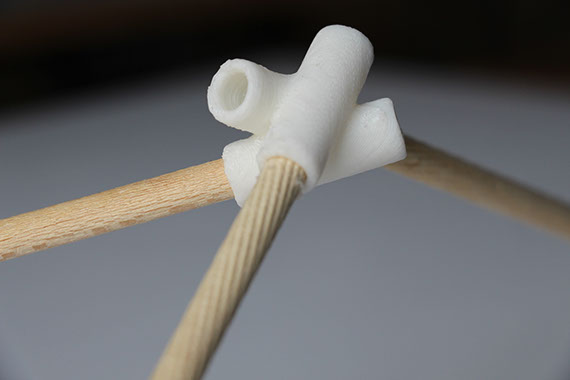

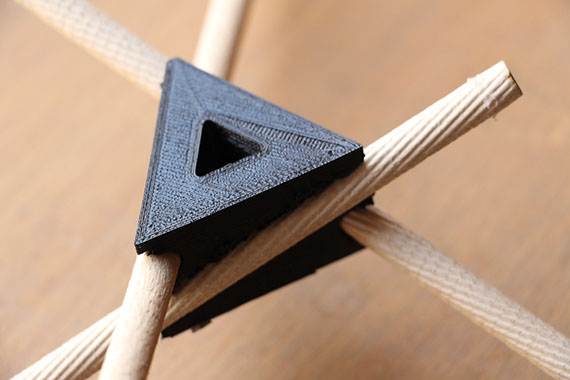

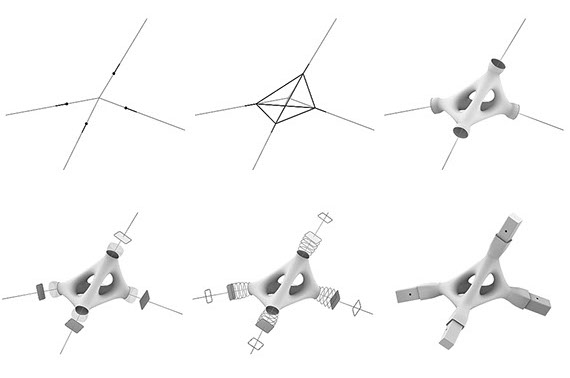

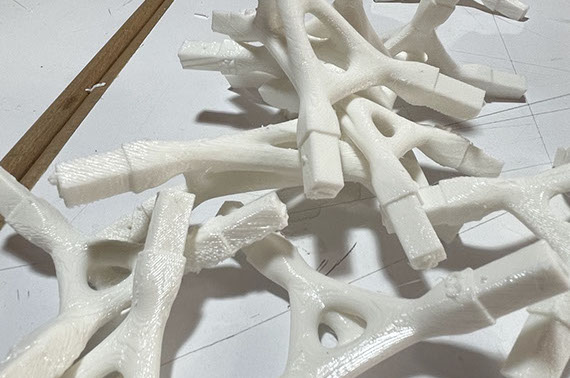

2022-1 & 2 | 3D Printed Structures

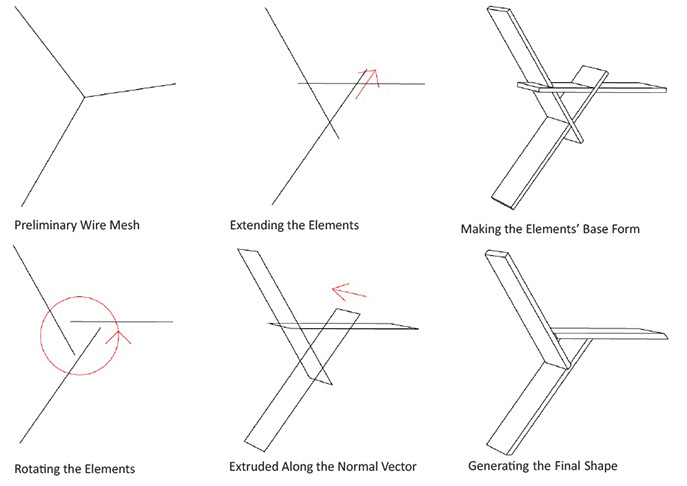

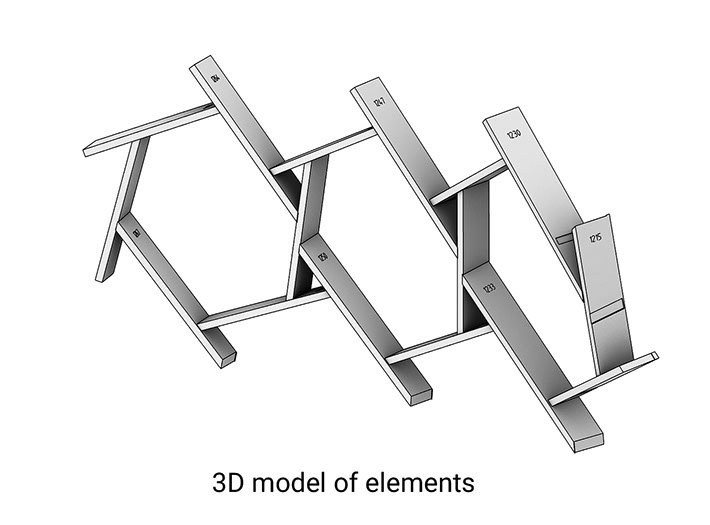

The focus of the workshop was on teaching the art of computational design and digital fabrication of spatial structures using 3D printing technology. I delivered a lecture on various 3D printing technologies and methods, and also prepared a tutorial video on how to print with an FDM printer. The students started with simple object fabrication, then designed & fabricated joints and nodes. An algorithm was meticulously developed to convert the wire mesh into a LOD400 BIM model to retrieve the most accurate fabrication data. Finally, all the joints were 3D printed, and the structure was assembled in a single day.

Role: Workshop coordinator, instructor, responsible for BIM algorithm

Construction & Installation

At Dahi Studio, along with architectural computing projects, ranging from solving complex geometric problems to automating processes, we also designed and constructed many unique projects; Projects mostly in the form of installations on a limited scale that could only be done with computational design and digital fabrication tools and knowledge. Some of the following projects are the ones I have contributed to as a Dahi member and some I have done individually.

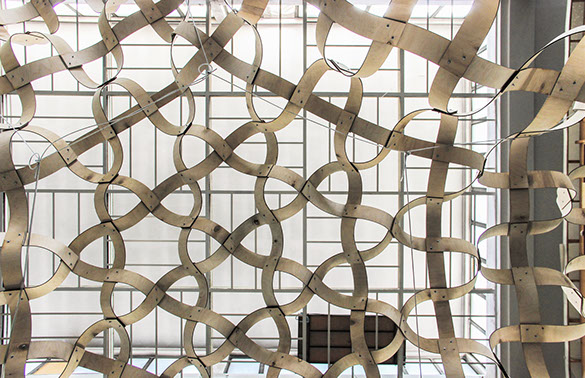

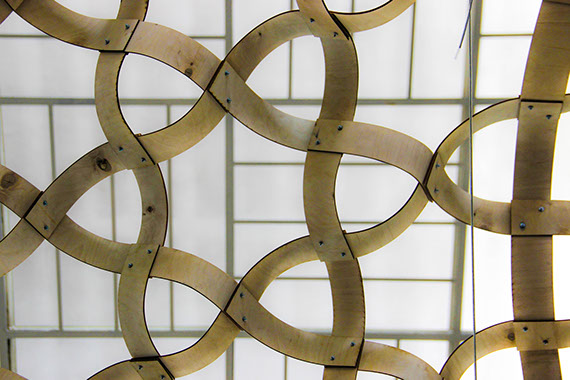

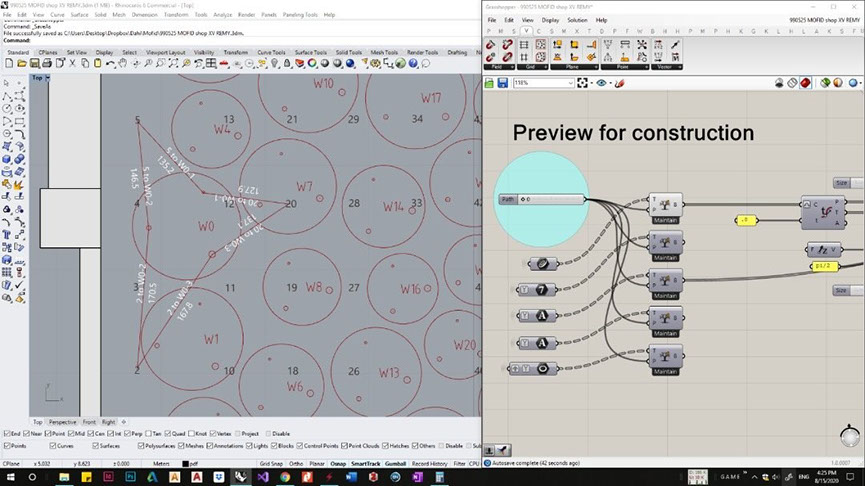

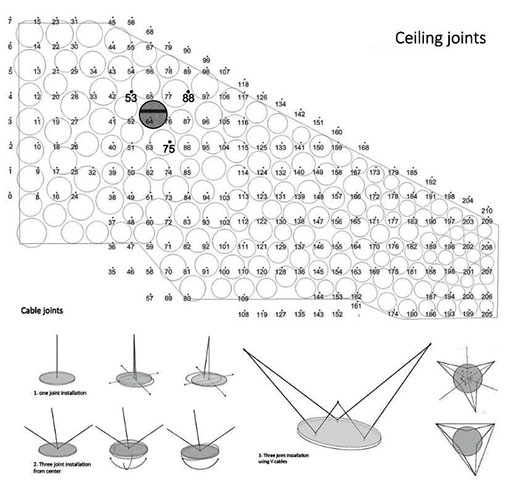

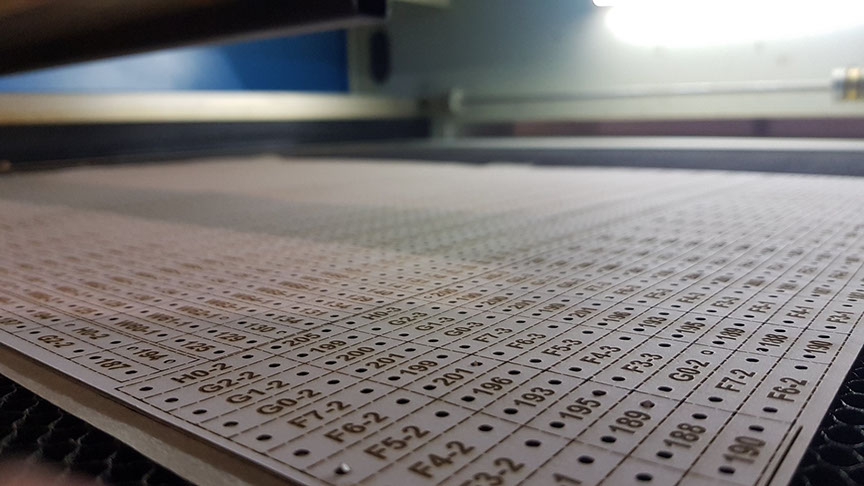

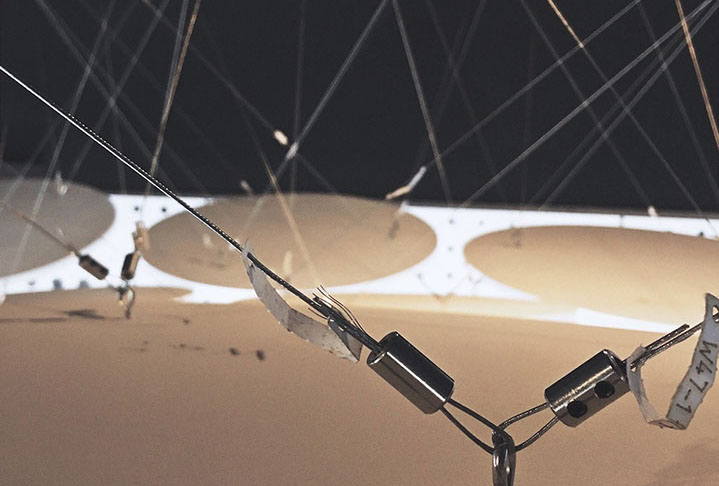

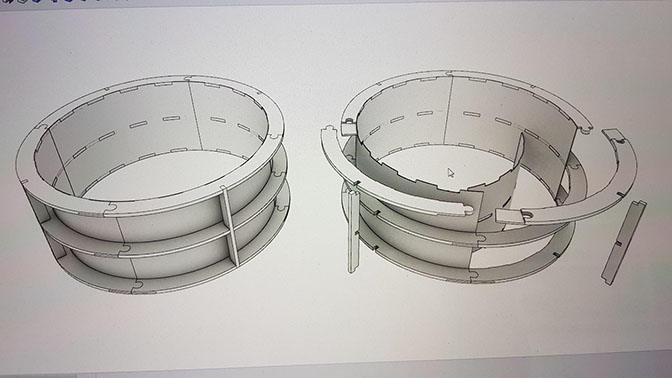

2020-8 & 9 | Floating Circles

As part of a project for Mofid company, we were tasked with installing a false ceiling to adjust the height of the space according to its needs. The hall was divided into several areas - a counter, a lobby, a sitting area, and a VIP meeting room - each with different height requirements. To address this challenge, the design team created a free-form false ceiling that could provide variable heights to each area.

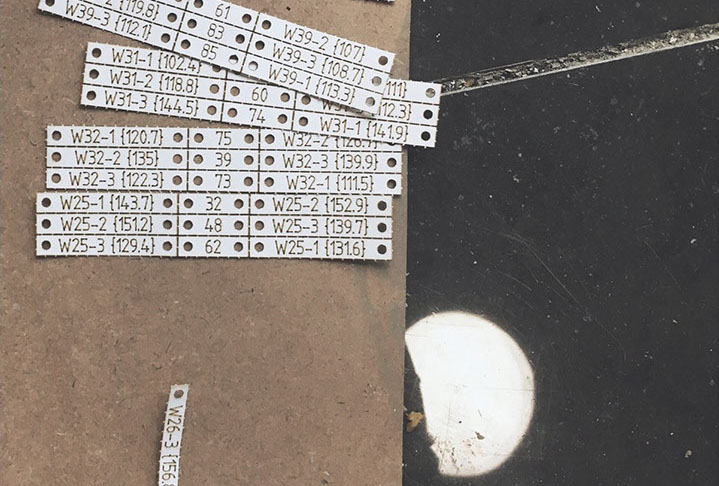

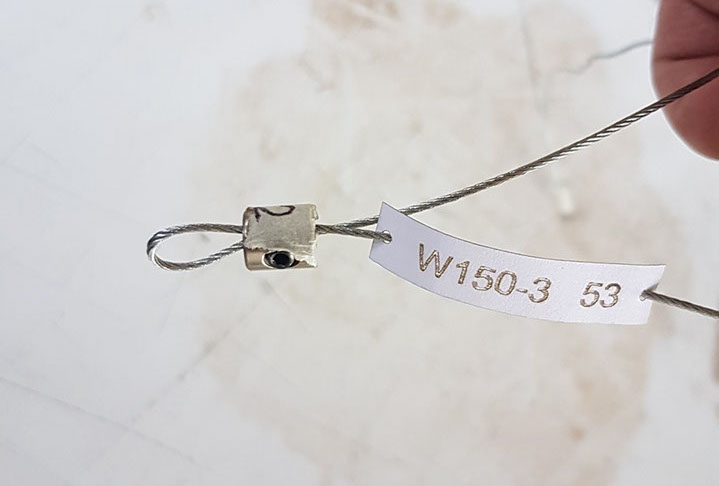

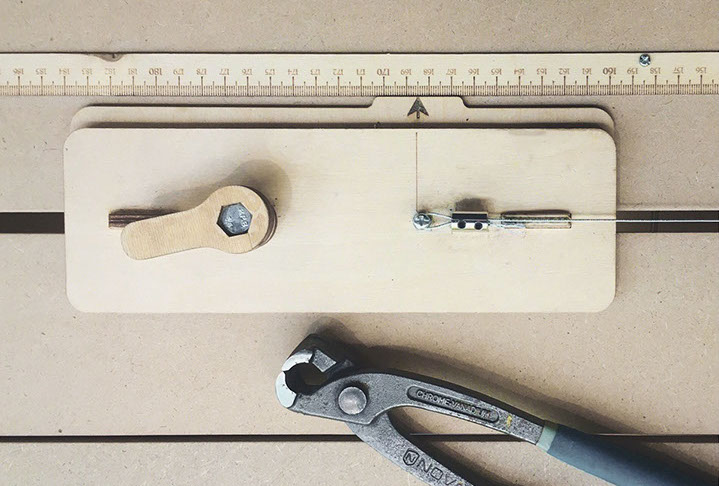

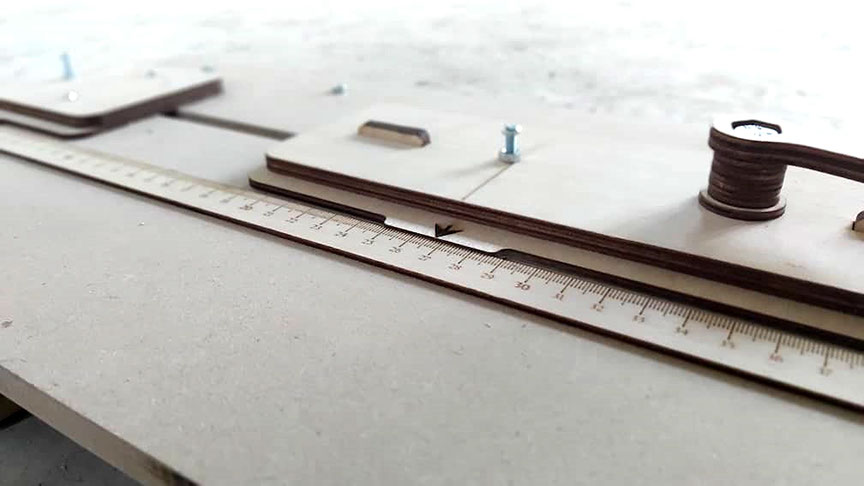

However, we could not add a secondary structure for the free-form ceiling, so we had to suspend lightweight panels from the existing ceiling. We proposed circles of varying sizes, with the radius increasing from the VIP meeting room to the entrance, to cover the hypothesized free-form surface. To suspend the circles in the right position and orientation, it was crucial to cut the cables with specific lengths. We used computational tools to retrieve the lengths table.

To measure the cables accurately and quickly, I designed and built a customized ruler. Additionally, I prepared the tags for the cables using our laser cutter. Three cables were needed for each circle, and we connected them to a grid of hooks to distribute the loads through the ceiling panels. Our solution allowed us to hang the circles in the right place, with the correct orientation, and without adding any extra weight to the ceiling.

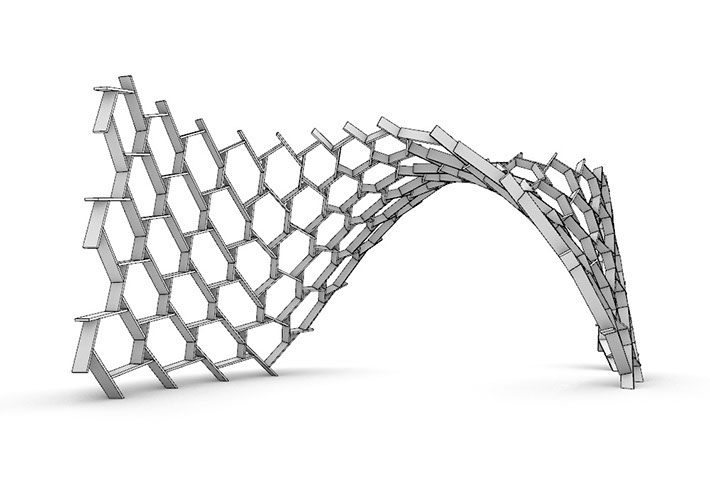

2020-12 | Integrity

We designed and fabricated this structure on behalf of the University of Art in December 2020, for the 8th Tehran National Sculpture Biennial. It was constructed with plywood sheets using the Nexorade structure technique, and all parts were digitally produced. The pavilion is a strip that rises from the ground and creates an arch with a twist. This twist was added to create a double curvature, which increases the strength of the structure.

I fine-tuned the proposed model in Rhino 3D and designed and manufactured the base footprint. Due to the complexity of the assembly, I developed an algorithm in Grasshopper to generate the necessary G-Codes for CNC milling process of the parts.

After the conclusion of this event, we transferred the structure to the campus of Baghe Melli at the University of Art.

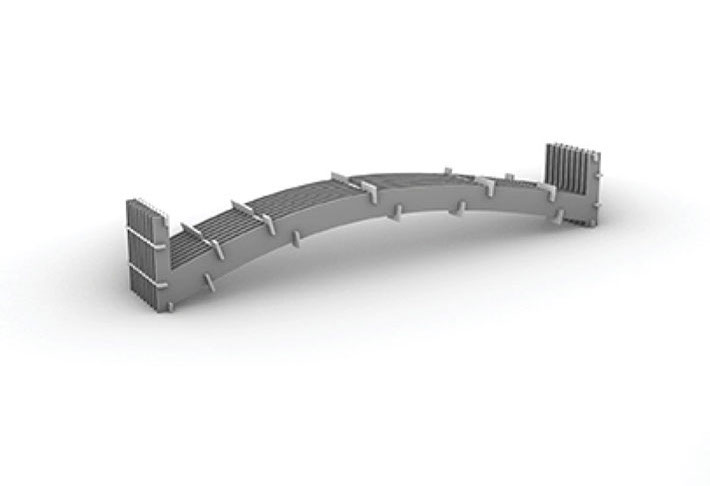

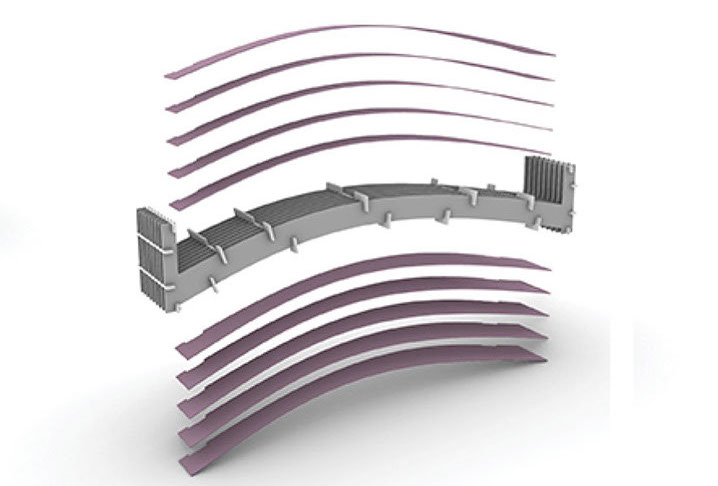

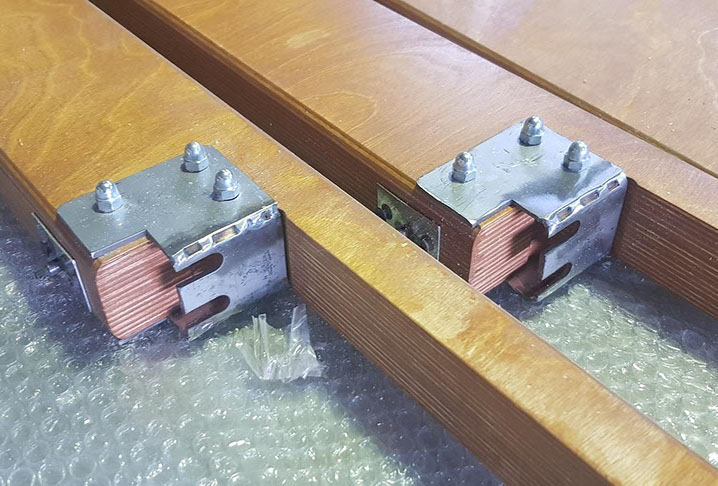

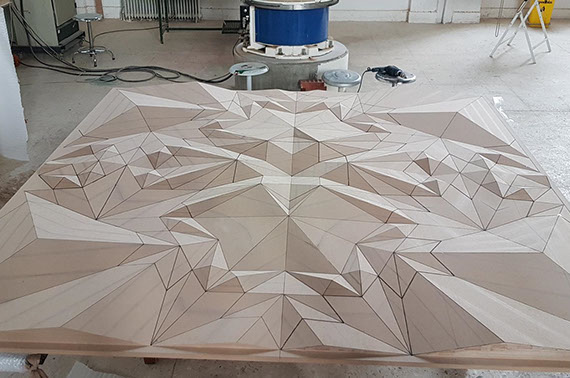

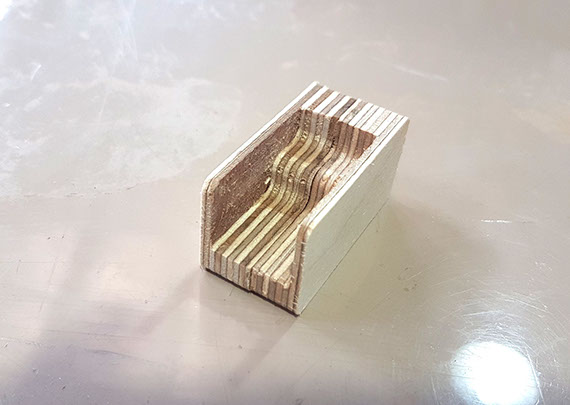

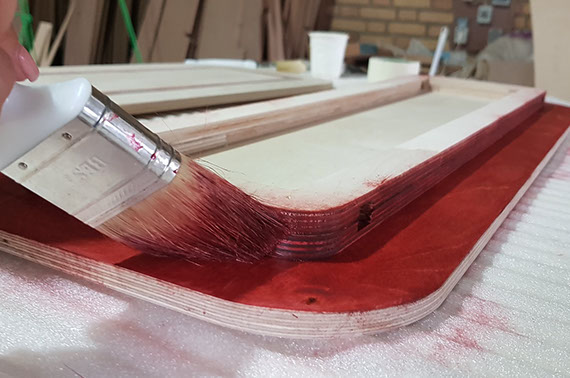

2020-12 to 2021-4 | Virginia Falls Facade

The task at hand was to construct and deliver the facade components for a residential building designed by Meanders Studio, located in Virginia (Canada). The manufacturing of the parts was to take place in Tehran. During the design phase, various factors such as the location of doors and windows, the amount of light the building would receive, and the mobility of the facade in front of the openings were taken into consideration. The biggest challenge was to create bent wooden parts without using steam, pressing or living hinge technique. To achieve this, an initial surface was designed in Rhino according to the existing limitations. The border shape of the facade parts was extracted from it using a contouring algorithm in Grasshopper. Each piece was made up of five layers of 9mm thick plywood. Shop drawings were then retrieved from the algorithm mentioned above. The layers were cut using a CNC milling machine. For each piece, a unique mold was designed with a specific curvature to allow the layers to be placed on top of each other and then glued together in a particular order.

Since each piece was unique, a tagging system was used to facilitate the construction and execution process. Once the parts were constructed, they were coated with vegetable oil and then wrapped in foam to protect them before being transferred overseas. A customized container was designed and manufactured with steel profiles to avoid any damage to the parts during transportation.

In this project, I designed and prepared the construction documents for the MDF molds. I also co-directed and participated in the assembly and coating process of the louvers.

<

>

<

>

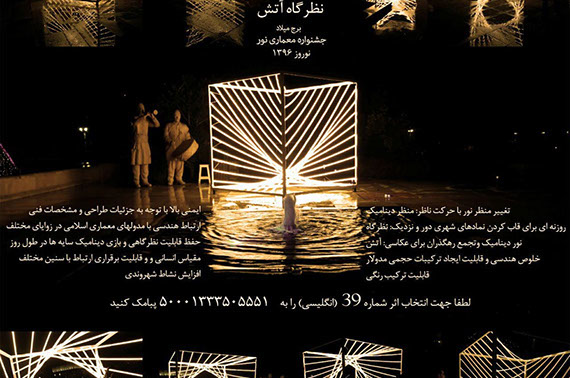

2017-1 & 2 | Light Deco

For the light architecture festival competition, we proposed a design of a black box with light strips. My role was to prepare the construction documents and supervise the installation of the LED strips. I also contributed to the painting of the box and the installation of some of the light strips, as I was personally interested in the project. Our team was awarded a certificate of appreciation for our design.

2018-7 to 2018-12 | Olympic Academy Head Quarter

As the designer and supervisor of the Olympic Academy Head Quarter project, I gained valuable experience in the interior design process from start to finish. I used 3D modeling and visualization to present different design options to the client, who then chose the furniture that I sourced and purchased. I also oversaw the execution of the project, ensuring the quality of the flooring, the MDF cabinets and drawers, the painting, and the lighting installation.

<

>

<

>

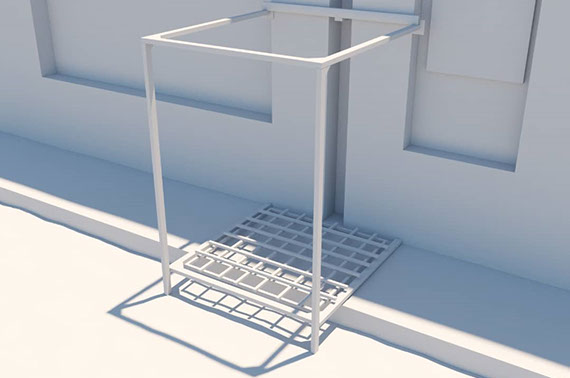

2020-5 & 6 | Robot Base

To equip the digital manufacturing laboratory of the University of Arts with a robotic arm, I designed and built the mold out of 3mm thick plywood for the concrete foundation, considering the rebars and the screws for the robot base. I then handed over the mold to the contractor and supervised the concreting operation.

2020-5 | Vacuum Room

In order to reduce the noise pollution of the industrial vacuum cleaner of the CNC machine, I designed a room in the outer body of the laboratory building and after obtaining the necessary materials, I built it with the help of my colleagues.

<

>

<

>

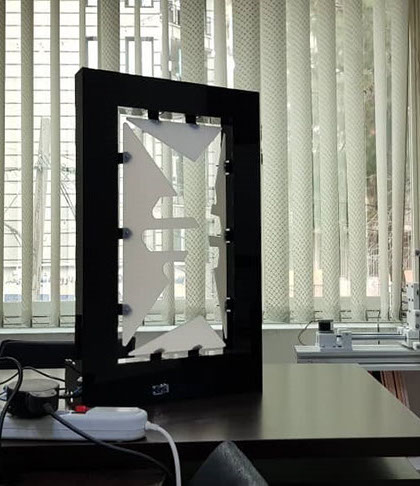

2022-8 & 2023-2 | Mirror Frame

For The Persian Fall project I designed and made a four-part mold for a mirrored panel, according to the client's specifications and the material and CNC machine constraints. Each part of the mold was composed of several layers of MDF, glued together. I then mounted the mold on an iron chassis, ready for the triangular mirror pieces to be attached. I managed to personally perform every stage of the project, from design to cutting, from chassis making to assembly. The experience I had before in making topography models was very useful in this project.

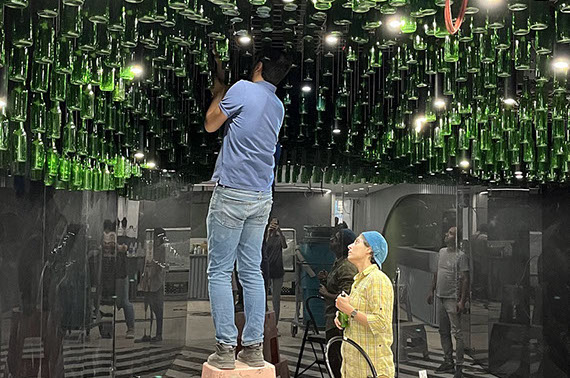

2023-1 | Tiada Lounge

We designed and built a parametric installation for the entrance of Tiada Lounge, using green bottles as the main element. I used computational tools to calculate the length and position of the screws needed to hang the bottles. Our team then cut and processed the 1-meter screws and attached the nuts to the bottle caps. Finally, we hung the bottles in a specific order on the steel mesh network that we had previously fabricated according to the plan. This project was one of the most fascinating and engaging ones that I participated in at Dahi Studio.

Teaching Experience

In the summer of 2019, I received an invitation from Tehran University to teach. The Dahi group valued education as one of their core missions, and since I had previous experience conducting workshops and teaching, I was invited to join as a lecturer. Being a former student of the university for almost a decade, I was honored and more than happy to accept the invitation. I lectured for two courses, "Computer-Aided Architectural Presentation” and “Computer-Aided Design And Fabrication”, for 5 semesters. Unfortunately, I couldn't continue my contribution due to the tight deadline and the many projects we had at Dahi Studio at the time. Below video is part of my lecture in which I explain various ways we can use digital technology in architecture. (2019-9 to 2022-2)

Product Design

Driven by my personal interest, I have used my knowledge and skills to design and fabricate various products over the years, both individually and collaboratively. Most of these products were designed by 3D modeling software and digitally fabricated using CNC-based machines.

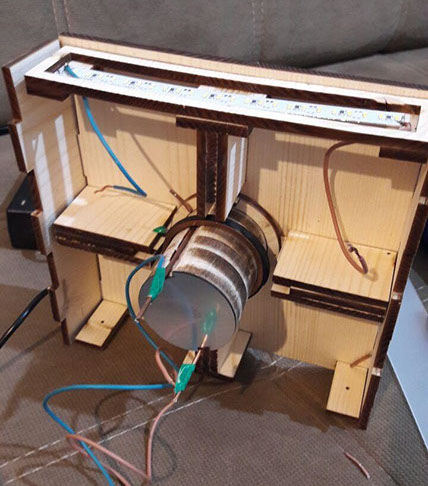

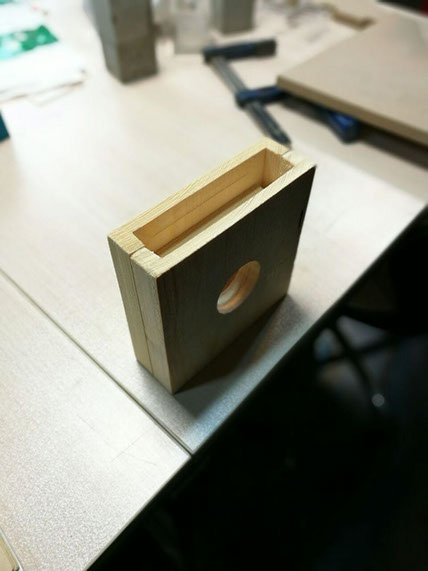

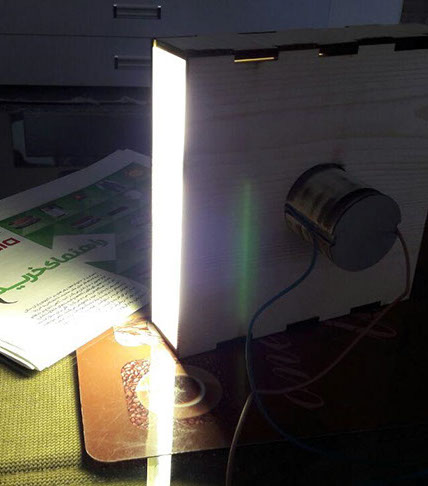

2017-2 to 2018-6 | Monji Light Fixtures

According to our contract with Monji Wood Lights company, we presented 16 unique ideas for light fixtures. Our design principles included using wood as the primary material, ensuring that they were customizable and affordable, and most importantly, innovative. We were successful in building a few prototypes, and the results were promising to say the least.

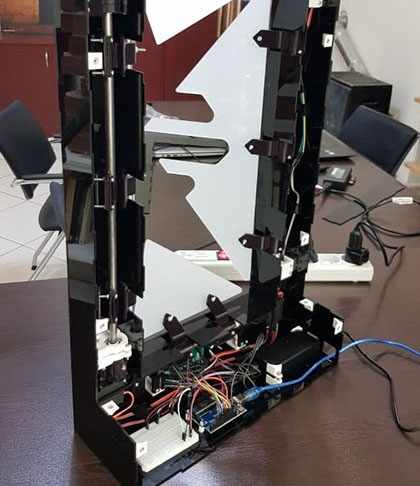

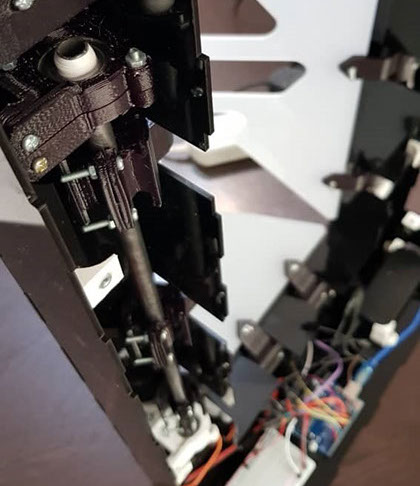

2019-1 & 2 | Responsive Window

For the responsive window shades, I designed and built the frame out of black Plexiglas. The walls of the frame were cut by a laser cutter. For the motorized parts, I utilized custom 3D-printed parts along with Servo motors. I developed the circuit using bread board, an LED, and a lumen meter module and programmed an Arduino Uno microprocessor the respond to the receiving light.

Writing the Arduino program was a challenging task. In order to eliminate the sensor noise and prevent the response to accidental events, like the shadow of a passing bird, I took the average of several inputs within a certain time range. It is worth noting that although I made the model of the window, the four triangular shades were not designed by me.

<

>

<

>

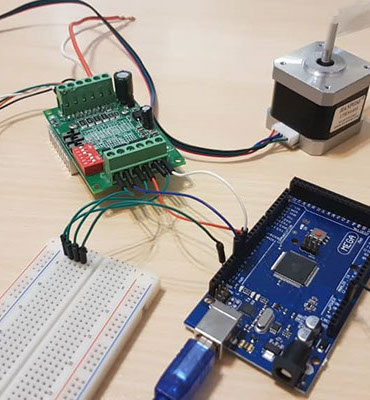

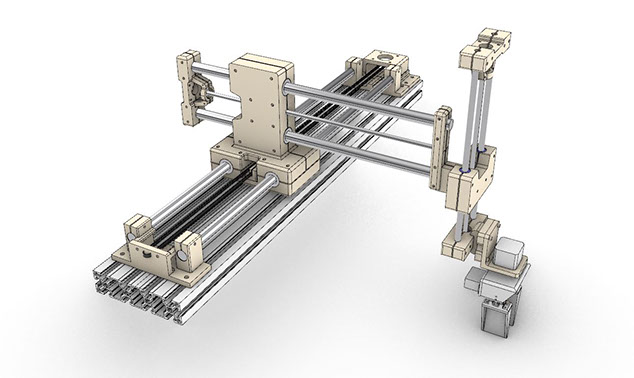

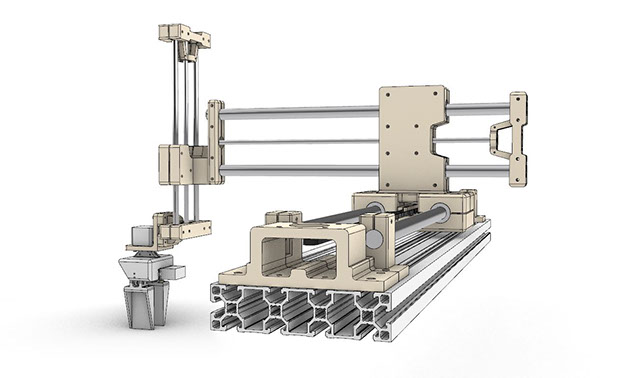

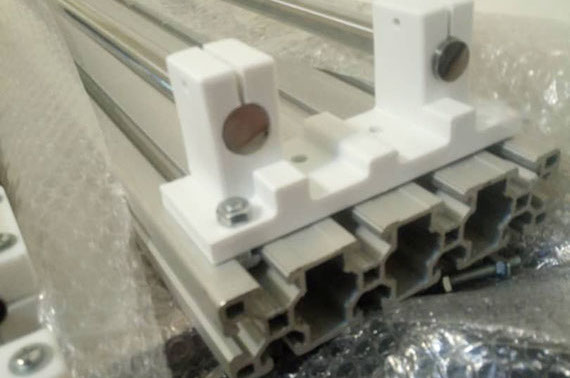

2018-9 & 10 | 5 Axis

One of our earliest digital fabrication projects was building a custom CNC machine. After acquiring our 3D printer, we decided to create a 5-axis CNC machine from scratch. I fine-tuned and optimized most of the parts in 3D modeling software, and then prepared the files for the printer. Following what I had learned, I 3D printed all the parts and assembled the CNC machine successfully. We even conducted some initial tests using an Arduino Mega as the microprocessor and stepper motors to control the first three axes.

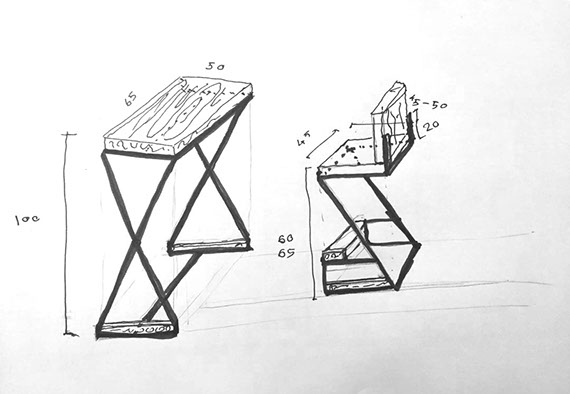

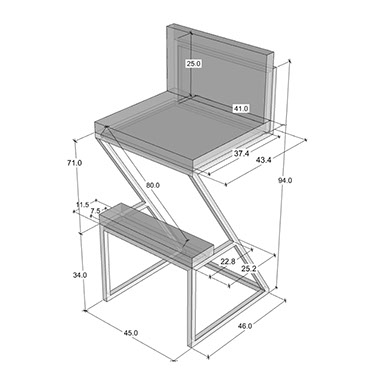

2020-2 & 3 | Table & Chair

To build these two chairs and the table I developed the primary sketch of the client. Based on that I made a revision and prepared the parts for assembly. I cut the profiles with a grinder machine and welded them together according the isometric documents with provided dimensions, then I applied the stainless coating and painted the profiles to build the chassis. Finally I connected the wooden parts with screws to the chassis and shipped the set to the client wrapped in bubble wrap.

<

>

<

>

2021-5 | Tistoo

We were commissioned by Tistoo Group to design and build furniture pieces for their new venture of developing and selling simple household furniture. Among the various furniture designs we created, two shelves were included. We prepared all the necessary documents for cutting and assembling the parts. After carefully sanding the plywood parts, we applied a finishing coating to give it a polished look. This project helped us gain the confidence to produce wooden furniture for homes in the future.

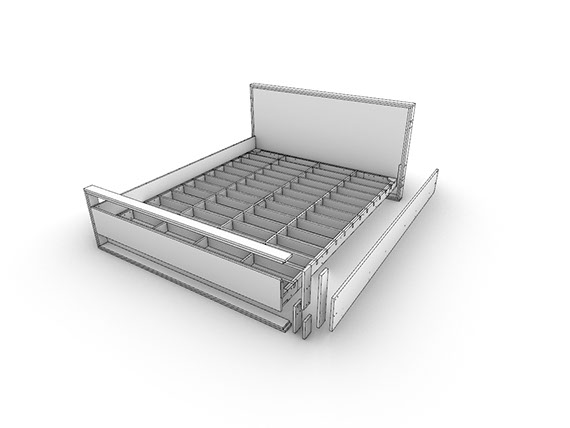

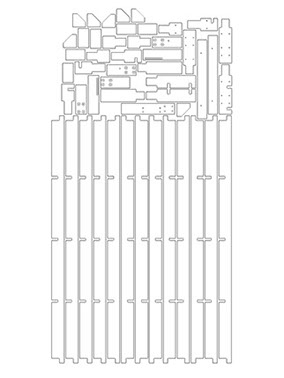

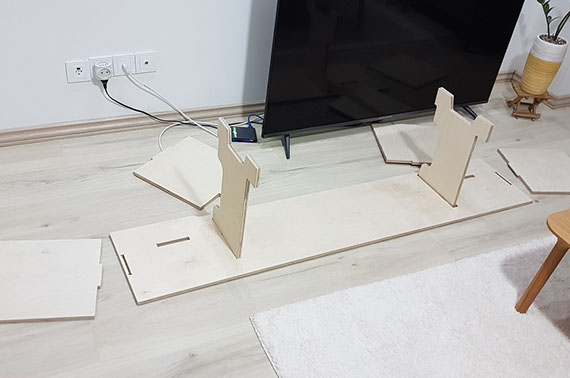

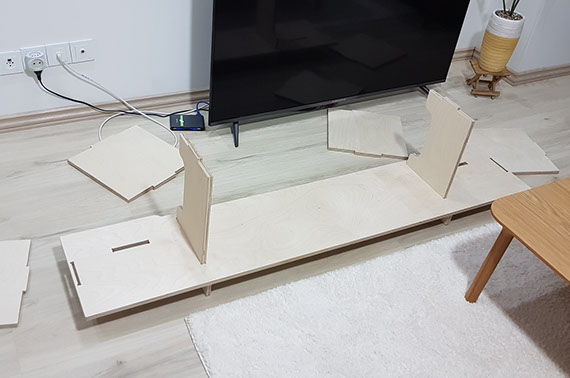

2022-7 & 9 | Bed & TV Table

I designed several pieces of furniture and accessories for our new home, including a bed and a TV table. I created all the intricate details and developed G-codes for the CNC milling machine. My wife and I did all the sanding and coating of the furniture ourselves, making it a valuable experience. Detail design has always been my favorite stage, and I took great care in designing the TV table parts so that they could be assembled without screws or connectors.

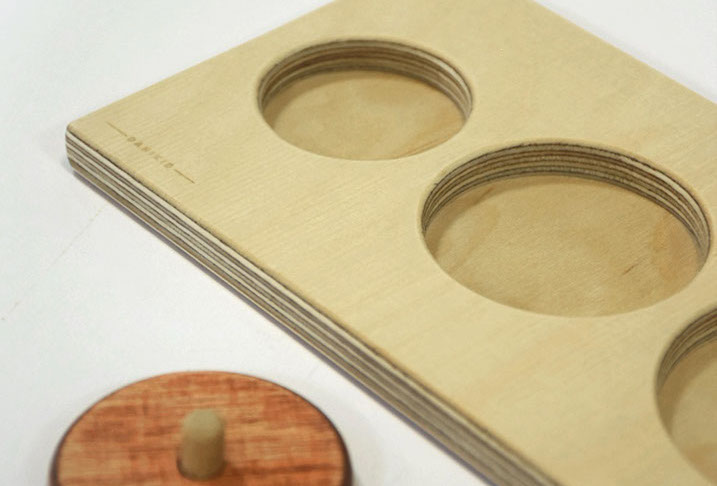

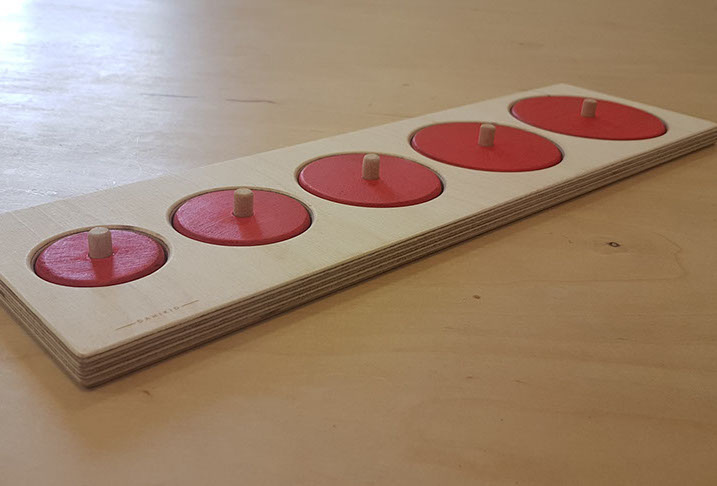

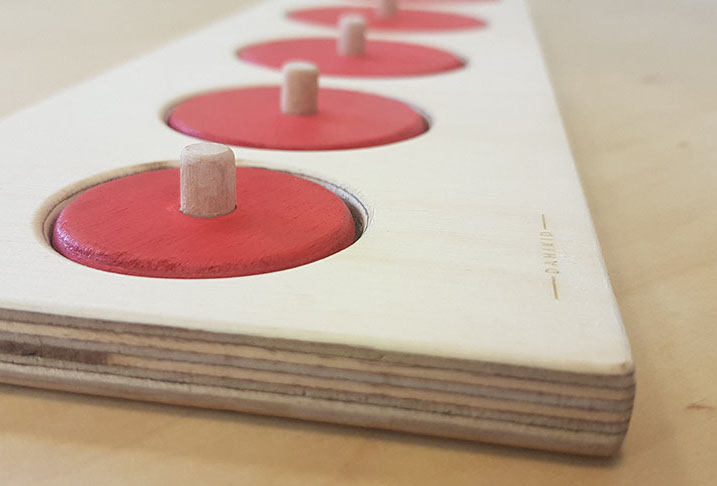

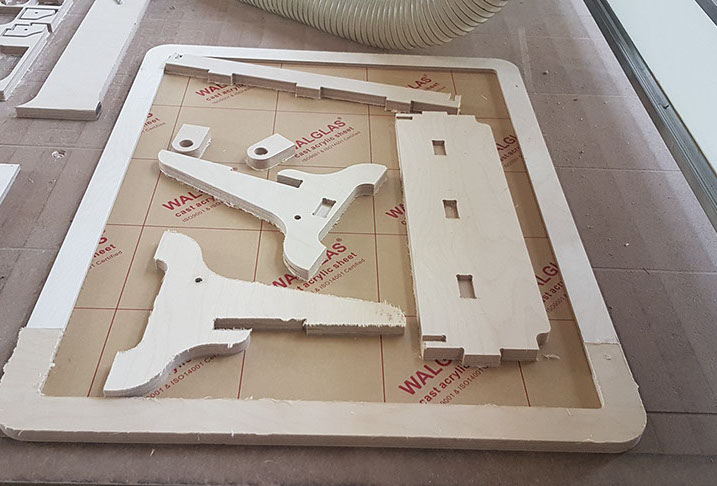

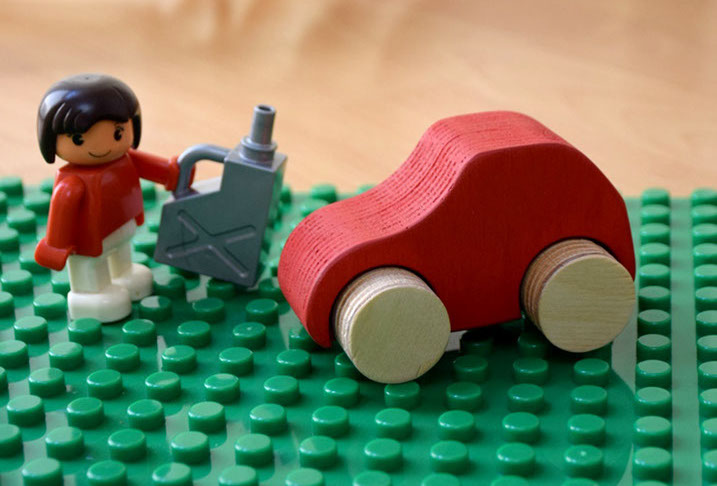

Dahi Kid

In 2021, I assisted my wife, Hanieh Omid, in launching the Dahi Kid project. The primary objective of this startup was to create educational toys and products for children based on the Montessori educational principles. These toys are designed to encourage children to experiment and learn through tactile stimulation. Digital Fabrication is widely used to enhance the quality of the products.

We believe that learning to handle objects is essential in developing children's fine motor skills. In designing our products, we focused on safety, ease of handling, packaging, and assembly for our users. We are continually working on new ideas and developing our products as a part-time activity. (2021-6 to 2022-3)

Chapter 3

Getting Professional

Master of Architecture

After working for Archi-Vision for more than a year, I decided to pursue my master's degree in architecture at the University of Tehran. This two-and-a-half-year academic program enhanced my professional skills by expanding my scientific knowledge and attention to construction principles and details. It also equipped me to work in a more professional setting. Below are some projects I worked on during this course.

Master of Architecture

(2012-9 to 2015-3)

University of Tehran

College of Fine Arts

School of Architecture

<

>

<

>

<

>

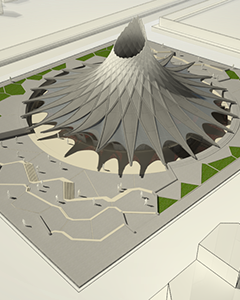

2013-7 | Banaye Iran

Banaye Iran was a project aimed at creating a building that could represent and exhibit Iran's culture and identity. As someone who has lived in Iran and studied its architecture for years, I proposed a semi-centric ascending structure inspired by one of its most iconic landmarks, Mount Damavand. The design is intended to welcome and embrace visitors while also paying tribute to the country's rich heritage.

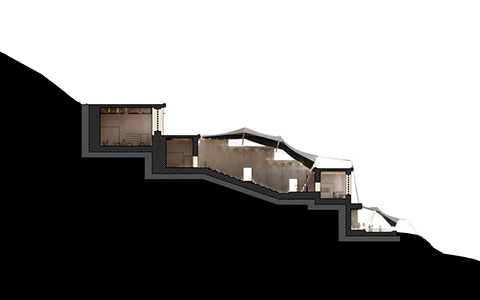

2014-2 | Nomad's Research Center

The Nomad's Research Center was a project aimed at designing a research center that would embody the Nomadic culture. I utilized the natural geography of the environment to position the building on a slope and opted for two vernacular materials, wood and clay, as the primary structure of the building. Additionally, I used nomadic woven fabric to cover the exterior spaces.

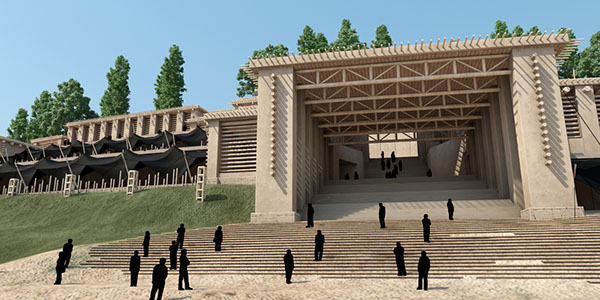

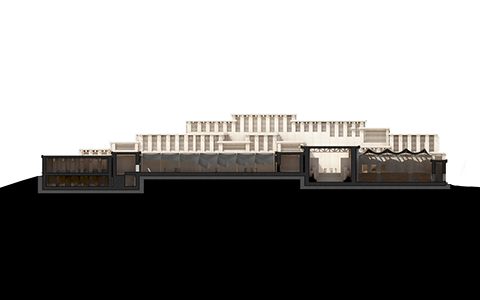

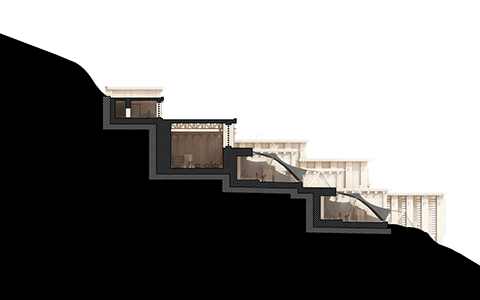

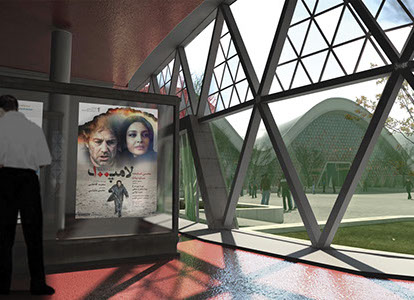

2015-3 | Film Festival Center

In the final project of the master's course, due to my interest in the cinema industry, I proposed a permanent center for holding film festivals in Tehran. Never before had a predetermined location been reserved for such an important event. I approached the design of this center as a cinematographer, creating each plan as a scene in a coherent and intentional story. The entire structure of the building resembles a film strip, with a complex and dynamic shape that reflects the highs and lows of a plot.

<

>

2014-4 to 2014-6 | Nosa Kish

We entered a design competition for a residential complex in Kish Island, drawing inspiration from the natural landscape. I used complex mesh modeling methods and geometric algorithms to achieve the goal.

<

>

2014-6 | Résidence Nairobi

The project of Residence residential building for a Kenyan client was carried out by our firm and I was involved in providing architectural visualization documents.

<

>

2014-9 | Villa Compound

We designed a compound of five villas in Nairobi and offered two options to the client. Both aimed to enhance the quality of life for the residents, which was the main goal of the competition.

<

>

2016-1 to 2016-2 | Holy Defense Museum

In the design competition of the Holy Defense Museum, our team used the structural elements of Iranian architecture, traditional spatial design, and the symbols of the Holy Defense and Martyrs' Memorial for conceptualization. I believe this project was one of the best designs of my career.

Nosa

Résidence

Villa

Museum

Matini-Moghadam Co.

In the spring of 2014, while I only had to submit a final project to receive a master's degree in architecture, I worked for 5 months with my esteemed mentor, Dr. Matini, and learned from him while contributing to several projects. After leaving his company, I presented my final project and graduated. (2014-3 to 2014-7)

I maintained a long-term collaboration with Dr. Matini, who trusted me to assist him in many of his future projects. I did my best to complete the tasks, mainly involving visualization and sometimes collaboration in the design process.

Acquired Skills:

- Time and resource management

- Advanced 3d modeling and architecture simulation

Equipped Tool-set :

Lumion, Microsoft Excel

Iran Arch Consultants

After earning my master's degree in architecture, I worked for a year at Iran-Arch, one of the leading engineering and architectural consulting firms. This experience helped me gain more insight into construction activities. (2015-4 to 2016-3)

Despite its positives, working for such a large company required a degree of subservience that was little compatible with my rebellious and ambitious nature. So, after one year, I left this company and, considering my age and experience, I started trying to stand on my own feet.

Website: www.iranarch.ir

Registered Name: شرکت مهندسین مشاور ایران آرک

Register No.: 16521

Acquired Skills:

- High rise buildings design criteria and considerations

- Curtain wall systems and paneling methods

2015-4 to 2016-3 | Hakim Towers

During this period, I collaborated on the Hakim Towers also known as Saman Faraz Towers project, where I created plaza alternatives and 3D models of the towers for further design assessments. Alongside preparing renders of the towers including above images, I also evaluated different curtain wall panel arrangements based on construction codes and proposed optimized options with minimal type variety using grasshopper algorithms.

<

>

Soor Esrafil Market

After leaving Iran-Arch at the age of 30, I began to work on independent projects with my peers. We were hired by the Soor Esrafil Market managers for six months to design and renovate the facade and the sales booths as well as some jewelry stores as an on-site engineer. I presented several alternatives for the facade, designed the sales booth interior furniture and installation, and supervised the jewelry store construction. (2016-4 to 2016-10)

Acquired Skills:

- Project management & coordination

- Construction of reinforced jewelry stores

- Glass Fiber Reinforced Concrete (GFRC) module production

- Website design & maintenance

Equipped Tool-set :

Autodesk Revit

2016-4 to 2016-10 | Soor Esrafil Market

I applied my algorithmic design skills to my first large-scale project in Soor Esrafil Market, where I presented our concepts effectively.

<

>

Chapter 2

First Steps as an Architecht

Bachelor of Architecture

I was admitted to study Bachelor of Architecture at the University of Tehran in the autumn of 2005. For the next 5.5 years, while I was gradually grasping the concept of being an architect, my visualization content changed from TV shows to architectural presentations. I worked on many presentation projects for friends and architectural firms in the late 2000's. In the last year of studying architecture for my bachelor's degree, I shifted my focus to McKneel's Rhinoceros 3D and its robust plug-in Grasshopper to design more complex models and solve geometrical problems.

Bachelor of Architecture

(2005-9 to 2011-2)

University of Tehran

College of Fine Arts

School of Architecture

Architectural Visualization

During my undergraduate degree in the late 2000s, I developed a specialization in visualizing architectural content. With over 20 years of experience, I have honed my skills in creating stunning visualizations for architectural projects and imparting my knowledge to others. My philosophy is that visualizing architecture should accurately represent the reality of construction, and highlight any design flaws before they can become costly and irreversible for the client. Additionally, it should showcase the beauty of the design to potential customers. Here are some examples of my previous work, which were predominantly completed before 2015.

2008-10 | Favorite Mosque (Ms. Mousavi)

2010-01 | LG Conceptual Kitchen Design Competition

2010-08 to 2010-10 | Mobile Library Design

2013-02 | Glasshouse (Mr. Haghnazar)

2013-05 | Chilak Commercial Center (Arxe Group)

2013-05 | Chilak Commercial Center (Arxe Group)

2013-06 | Power Hotel (Arxe Group)

2013-06 | Power Hotel (Arxe Group)

2014-6 | Résidence Project in Kenya

2014-6 | Résidence Project in Kenya

2014-6 | Résidence Project in Kenya

2014-9 | Villa Compound in Nairobi

2016-1 & 2 | Holy Defense Museum Competition

2016-1 & 2 | Holy Defense Museum Competition

2016-1 & 2 | Holy Defense Museum Competition

2016-10 | Sarpolzahab (Dr.Matini)

2017-4 | Residential Interior (Mr. Fatehifar)

2017-4 | Residential Interior (Mr. Fatehifar)

2019-5 | Gholhak Residential (Mrs. Razavi)

2019-12 to 2020-2 | Motel Ghoo Commercial Center Competition

Archi-vision

In the spring of 2011, I graduated and began working at Archi-Vision, an engineering firm that specializes in designing and constructing spatial structures. I enjoyed my time at the firm as the work environment was both professional and friendly. Archi-Vision's manager, Mr. Jamili, and staff helped me become a disciplined and meticulous architect, shaping my future in the field. It was during this time that I decided to pursue my studies further. (2011-3 to 2012-8)

Website: www.archi-vision.com

Registered Name: شرکت طرح و فن آوری معمار رای

Register No.: 14382

Acquired Skills:

- Team work and collaboration

- Basics of space structures design and manufacturing

- Precision in design and paying attention to details

- 3D NURBS modeling

- Algorithmic design and geometrical problem solving

Equipped Tool-set :

AutoCAD, Rhinoceros 3D, Grasshopper

.jpg?crc=4134804704)

<

>

2011-4 to 2012-5 | Laar Stadium

On my first assignment, I had to examine the stadium's initial plan to determine whether there were any obstructions that could potentially block the spectators' views. To do this, I created a 3D model of the seats and analyzed each spectator's view of the field. I discovered that the plan needed to be corrected because some of the views were impeded by the stadium's structure. My next responsibility was to create a 3D mesh line of the diagonal columns and the roof to assist our construction engineer. I was thrilled that my 3D modeling abilities enabled me to solve a real problem. I was also impressed that the design firm took the time to evaluate their design.

2011-9 | Helipad Design

For this project, our goal was to create a helipad that meets all of the legal requirements for a high-rise tower. In order to ensure that we met these requirements, I conducted thorough research into all relevant codes and regulations, paying special attention to the necessary dimensions, height, and orientation of the landing pad. To create the helipad structure, we utilized our company's standard space structures system.

Laar 3000 Seat Stadium

Helipad Design

Chapter 1

The Beginning

Since I was a child, I have had a passion for animation. I used to watch cartoons with amazement and dreamed of creating my own animated movie someday. At the age of 15, I took my first steps into the world of 3D modeling and animation. Since then, I have been constantly learning and improving my skills as a visual artist. With the guidance of my uncle, I created several teasers and short animations for TV shows. I also excelled in Math and Physics, which led me to pursue a degree in Architecture at the University of Tehran, the best university in Iran.

3D Modeling & Animation

Since 2001, I have been working as a 3D modeler and animator, producing numerous teasers and intros for national TV shows, particularly during the early 2000s. I have created animations covering various topics such as news and health, employing my skills in creating animated environments, charts, and diagrams. However, I have not yet had the chance to work on character animation.

Acquired Skills:

- 3D mesh modeling and texturing

- Rendering

- Basic animation and editing

Equipped Tool-set:

3D Studio Max, Adobe Photoshop, Adobe Premiere